Blog

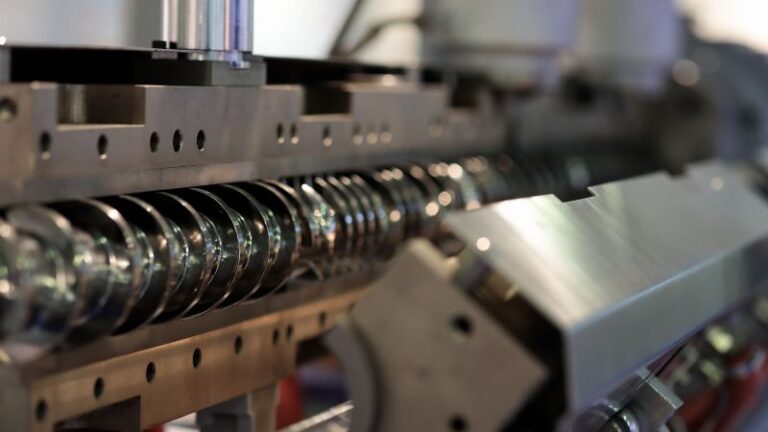

What is Step Turning?Overall Guide for Beginners

What is Step Turning? Step turning is a type of turning operation done on a lathe machine. In…

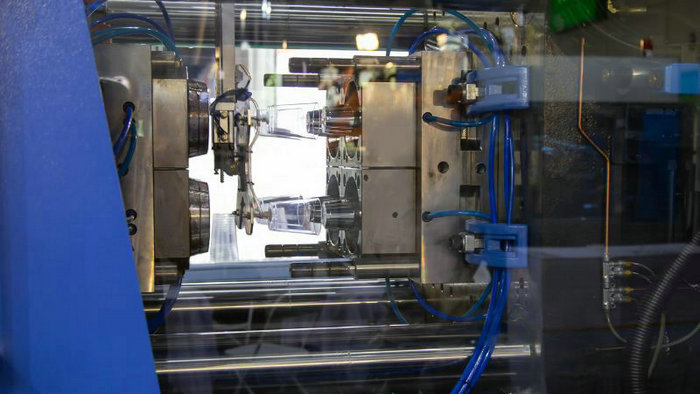

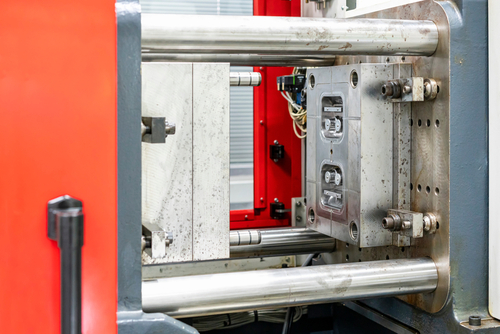

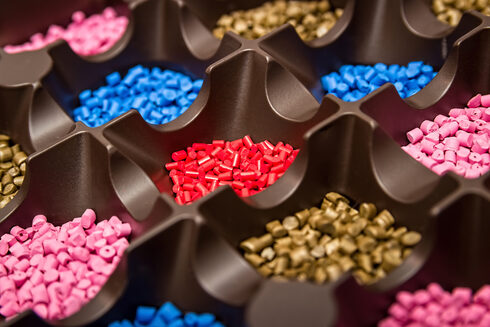

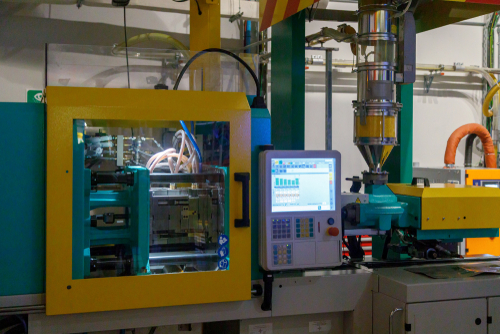

Types of Injection Molding Technology: Guide to Process and Materials

What is Injection Molding Technology? Injection molding is a manufacturing process. By injecting melted materials into…

What is spotface: Understanding this Essential Machining Feature

A spotface is a machined area on a part that creates a flat, smooth surface…

What is Swiss Machining and How to Use for Precision Manufacturing

Swiss machining is a precise way to cut high precision parts from metal or plastic. It…

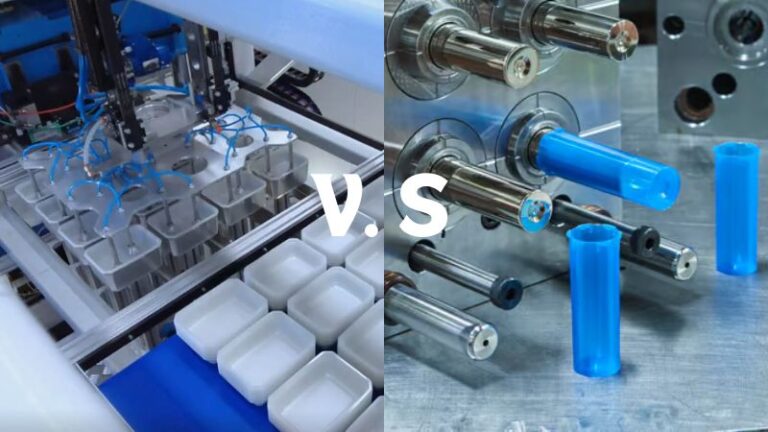

Difference Between Extrusion and Injection Molding: Key Processes, Applications, and Advantage

You might notice the terms extrusion and injection molding when learning about how plastic products…

Injection Molding vs Vacuum Forming: Key Differences, Benefits, and Applications

When you need to create plastic parts, choosing the best method is important. Injection molding…

Brief History of Plastic Injection Molding: Innovations and Milestones

Plastic injection molding started in the late 1800s as a way to create precise plastic…

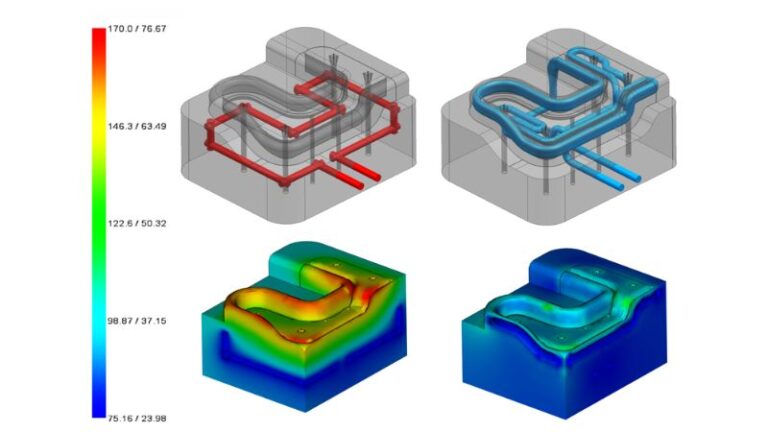

Unlocking Conformal Cooling Channels: Benefits of Additive Manufacturing

What is Conformal Cooling? Conformal cooling represents a significant advancement in manufacturing technology, particularly for…

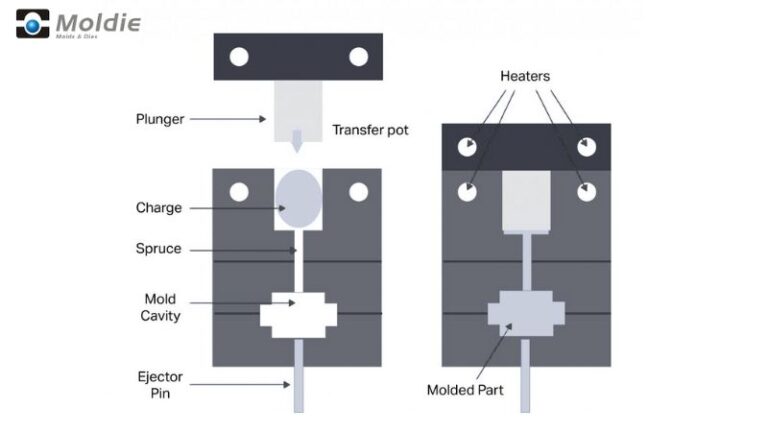

What is Transfer Molding: Advantages and Disadvantages

Transfer molding is a manufacturing process where pre-heated polymer material is forced into a closed…

Conformal Cooling vs Conventional Cooling: How to Choose?

Why Cooling a Mold is Important? Keeping the cost per unit low in injection molding…

Moldie Insert Molding Explained – What is Insert Molding?

Overview of Insert Molding Insert molding happens when you place a pre-formed part (the insert)…

Industrial Robots in Manufacturing Industry – Moldie Automation

Robots have become a game-changer in manufacturing, bringing speed, precision, and improved safety to…

Injection Molding Machine Maintenance: Simple Tips for Keeping Equipment

Keeping your injection molding machines in top shape requires a mix of regular care, proper…

Difference Between Tg and Tm in Plastic Injection Molding

What is Transition Temperature (Tg)? Glass Transition Temperature (Tg) refers to the point where a…

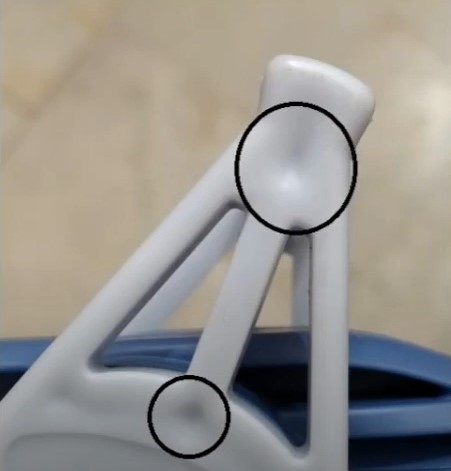

Mold Parts Plastic Boss Design in Injection Molding

When indulging in injection molded parts design, bosses are small but vital features. They’re the…

Short Run Injection Molding: Quick Solutions for Small Batche

Injection molding involves creating parts by injecting molten plastic into a mold. This mold, usually…

Moldie Successfully Showcases at Fakuma 2024 in Friedrichshafen

Moldie is pleased to announce our successful participation at Fakuma 2024: The Plastic Show, held…

What is Type II Anodize? Type II VS Type III What are the Differences

What is Type II Anodizing? Type II anodizing is a method used to treat aluminum.…

What is Type 3 Anodizing? Type III Hardcoat Anodize Explained

What is Type 3 Anodizing? Type 3 anodizing, often known as hard anodizing, is used…

How Does Electroplating Work? A Detailed Explain

What is Electroplating Electroplating is the process that coats materials with a thin layer of…

Draft Angle in Injection Molding: What is it?

Draft angles are a key aspect of mold design that affect both the quality and manufacturability…

Thermoforming vs Injection Molding: Key Differences Explained

What are Thermoforming and Injection Molding? Let me explain it in a simple way that’s…

Best Plastic Injection Molding Companies – Moldie

Plastic injection molding is a process you might use if you want to create numerous…

PVC Injection Molding 101: All the Things You Should Know

Polyvinyl Chloride (PVC) injection molding stands out as a versatile and reliable manufacturing process that…

What is Polypropylene Injection Molding? PP Injection Molding

Polypropylene injection molding is a highly efficient and versatile manufacturing process used to produce a…

Blow Molding Vs Injection Molding: What are the Key Differences?

While both blow molding and injection molding serve the fundamental purpose of shaping plastic materials,…

Understanding Rubber Injection Molding: Process, Molds, and Parts

Rubber injection molding is a versatile and efficient manufacturing process that has revolutionized the production…

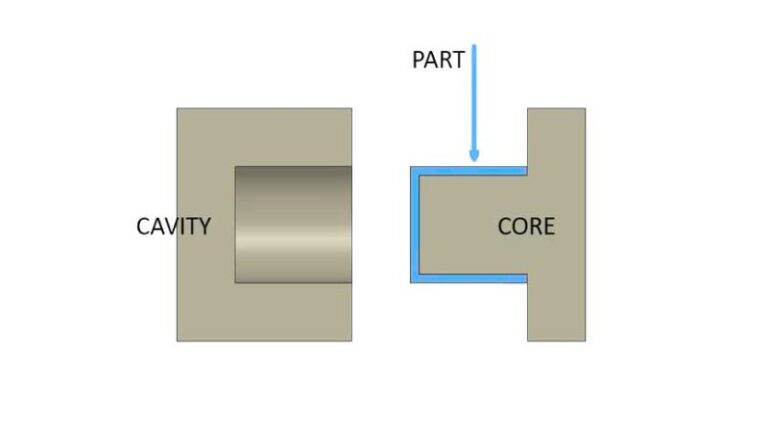

Injection Mold Cavity: Understanding Its Role in Manufacturing

Injection molding is a popular method used to create plastic parts by injecting molten plastic into…

An Overall Guide to Injection Molding Tolerances

Injection molding tolerances define the permissible limits of dimensional variation in molded parts. Understanding and…

Mastering Injection Molding Cores: Enhance Design and Quality

The heart of Injection molding lies the mold core, a critical component that shapes the internal…

Moldie Invites You to 29. Fakuma

Dear Valued Partners and Clients, Moldie will be participating in the 29. Fakuma, the world’s leading trade event…

Moldie Invites You to Die Casting Congress & Exposition 2024

Dear Valued Partners and Clients, Moldie will be participating in the Die Casting Congress & Exposition…

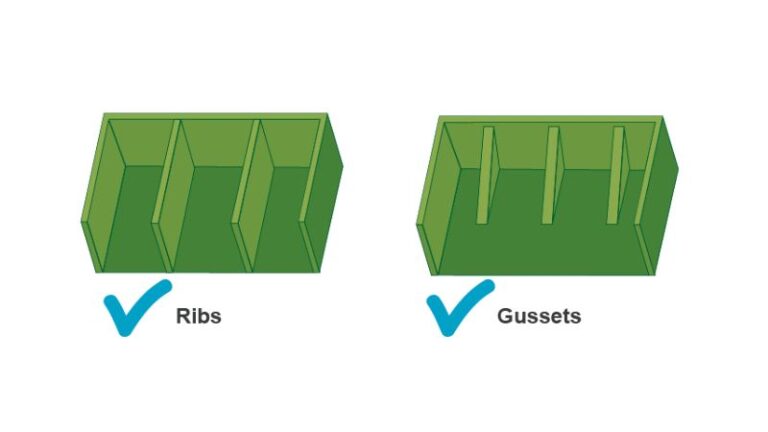

Injection Molding Rib Design: Essentials for Optimal Part Strength

Proper rib design is essential for achieving optimal part strength while maintaining manufacturability and cost-effectiveness.…

Optimizing Injection Molding Finishes for Aesthetic and Functional Use

What is a Surface Finish in Injection Molding? In the realm of injection molding process,…

Causes and Prevention Strategies of Injection Molding Warpage

Warpage can be annoying. For manufacturers and product designers alike, it is important to understand…

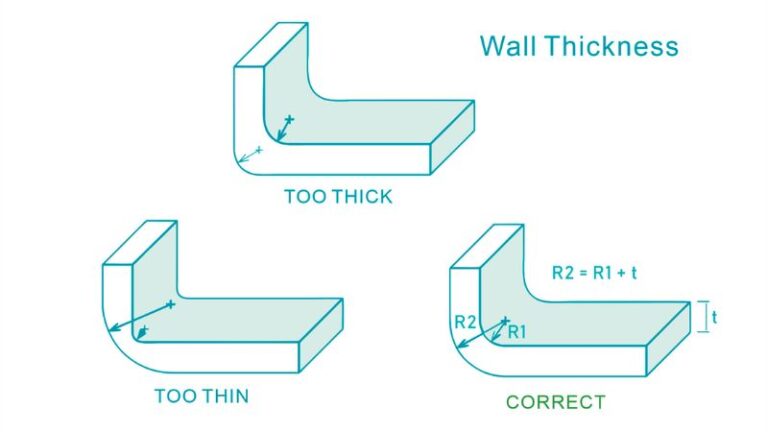

Plastic Injection Molding Wall Thickness Overall Guide

From understanding the basics of wall thickness to navigating material-specific considerations, this guide covers essential…

Types of Injection Molding Technologies: An Overview of Modern Methods

Main Types of Injection Molding Technologies Injection molding is one of the most widely used…

Flow Lines Injection Molding: Minimizing Defects for Improved Product Quality

What Are Flow Lines in Injection Molding Flow lines are a common defect encountered in…

Injection Mold Cooling: Optimizing Cycle Time and Quality

Injection Mold Cooling System Design The cooling system ensures uniform cooling and efficient temperature control…

What are the Types of Injection Mold: A Comprehensive Guide

Injection Mold Classification If you’re assessing injection molds, it’s essential to grasp the classification system…

Moldie Showcases Innovative Products at NPE2024, Leading the Plastics Industry in New Directions

May 6th to 10th, 2024, the renowned NPE2024 exhibition in the global plastics and rubber…

Injection Mold Temperature: Optimizing for Manufacturing Efficiency

Injection molding is one of the most widely used manufacturing processes for producing high volumes…

Die Casting vs Metal Injection Molding: What are the Differences?

What Is Die Casting? Die casting is a manufacturing process that involves pouring or injecting…

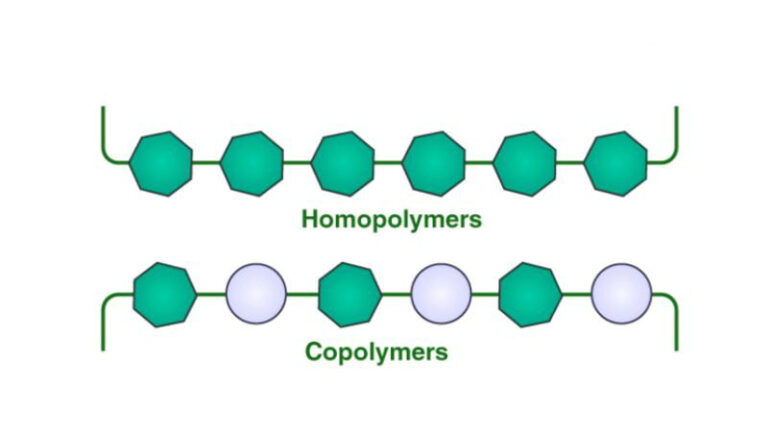

Homopolymer vs Copolymer: Key Differences and Applications Explained

Understanding the differences between homopolymers and copolymers is essential for selecting the appropriate material for…

What is a Copolymer: Understanding the Basics of Polymer Chemistry

Understanding the fundamentals of copolymer chemistry is crucial for anyone interested in polymer science, materials…

Injection Molding HDPE: All You Should Know

You may not be familiar with HDPE and injection molding. HDPE molded parts are commonly…

Flash Issue in Injection Molding: Streamlining Production for Efficiency

Flash is a common defect in plastic manufacturing that can significantly impact production efficiency. As…

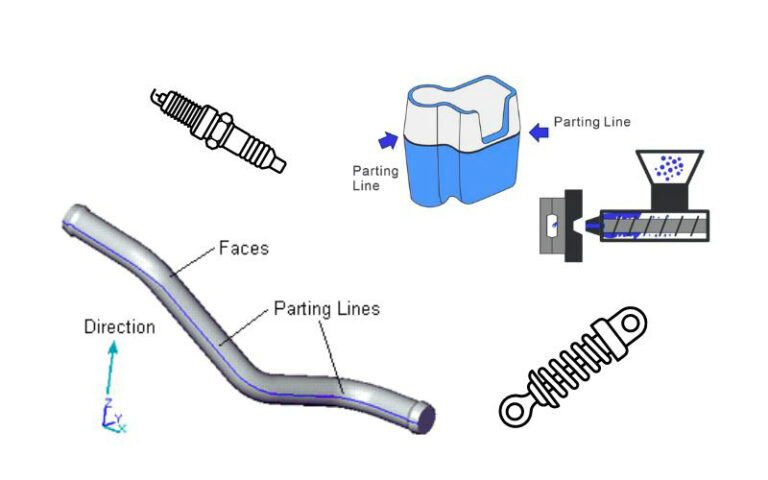

Parting Line in Injection Molding: Understanding Its Role in Product Quality

The parting line is an injection molded plastic junction where halves meet during the molding…

Thermoplastics vs Thermosets: Breaking Down the Differences

Thermoplastics and thermosets are two main types of plastics that are commonly used in various…

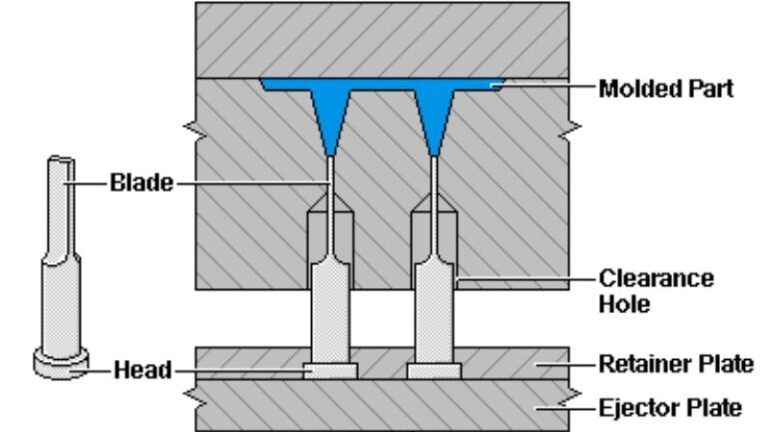

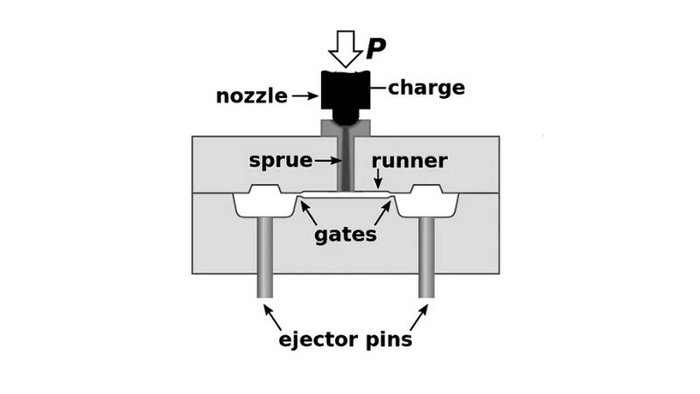

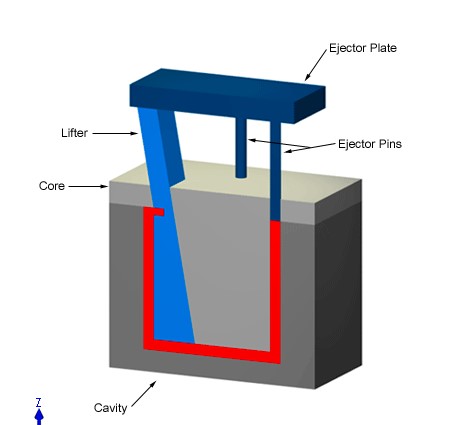

Ejector Pins Injection Molding: Key to Clean Mold Release

Injection molding is like running a really cool assembly line in miniature, and ejector pins…

How are Thermoplastics Manufactured: A Snapshot of Production Methods

Thermoplastics are one of the most widely used types of plastics today due to their…

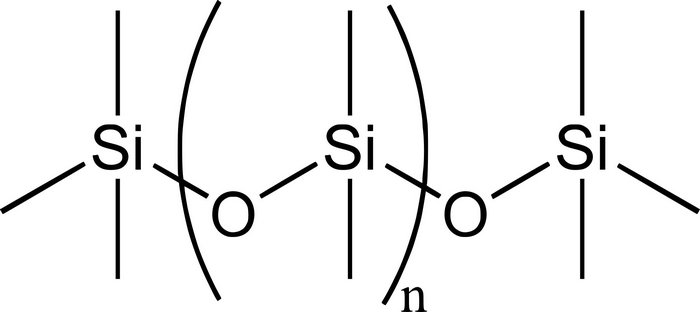

Unveil of Injection Molding: An Ultimate Guide to Silicon Molding Process

Silicon molding is a manufacturing process that uses liquid silicone rubber to create molds. The…

What is Molding Polycarbonate? A Complete Guide to Polycarbonate Injection Molding

Introduction to Polycarbonate Molding Polycarbonate molding is a technique you can employ to craft items…

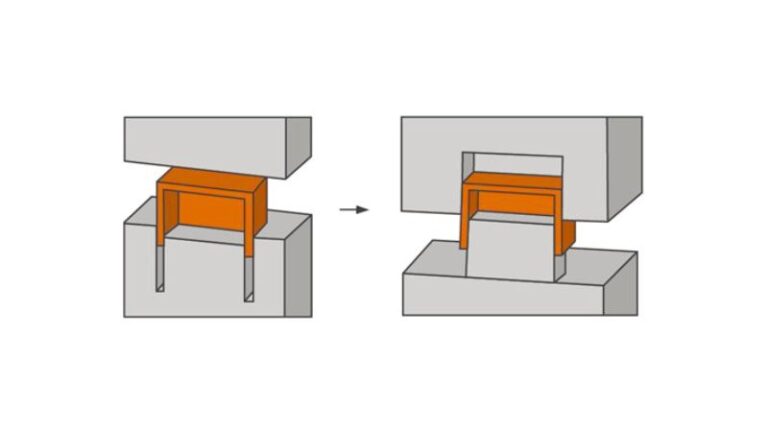

Compression Molding vs Injection Molding: What is the Difference

Compression molding and injection molding are two of the most common manufacturing processes used for…

Compression Mold: A Friendly Guide to the Process and Benefits

Compression molding is a manufacturing process commonly used to produce items made from plastic or…

Clear Plastic Injection Molding: Understanding the Basics

Introduction to Clear Plastic Injection Molding When you want to create transparent plastic parts with…

Acrylic Injection Molding: An Ultimate Guide for Beginners

Acrylic injection molding is a popular method for producing clear, strong, and durable components made…

What is Gate Injection Molding? A Comprehensive Overview

Injection molding is a widely used manufacturing process for producing plastic parts by injecting molten…

Benefits of Screen Printing on Plastic: Key Advantages Explained

Screen printing is a versatile and popular method for applying designs and images to various…

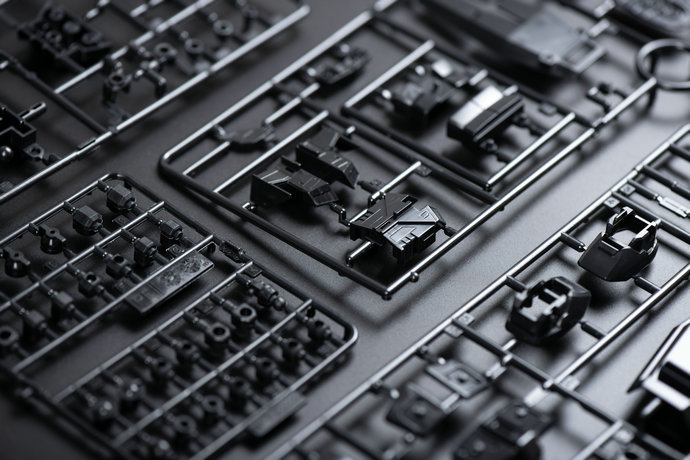

What is the Function of Plastic Sprue in Injection Molding? A Concise Overview

Injection molding is a manufacturing process that creates plastic parts by injecting molten material into…

Understanding Injection Mold Costs: A Comprehensive Breakdown

Injection molding is a widely used manufacturing process that enables the production of complex plastic…

Zinc Alloy Casting

Die casting uses high temperatures and pressure in manufacturing molten metals and alloys to generate…

Zinc vs. Aluminum: What Are Their Differences

The die casting industry primarily encompasses aluminum and zinc alloys die casting, which has seen…

Aluminum High Pressure Die Casting: An In-Depth Guide

Concept Of High Pressure Die Casting High pressure die casting (HPDC) is a metal casting…

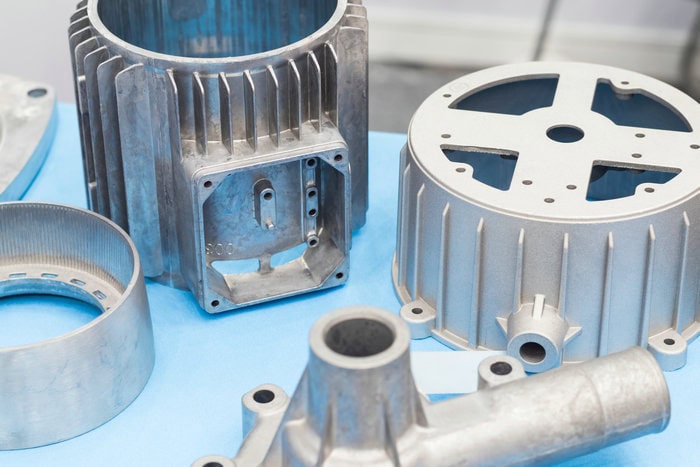

Aluminum Die Cast

Aluminum die casting is a mainstay manufacturing process that’s existed since the 19th century. This technique…

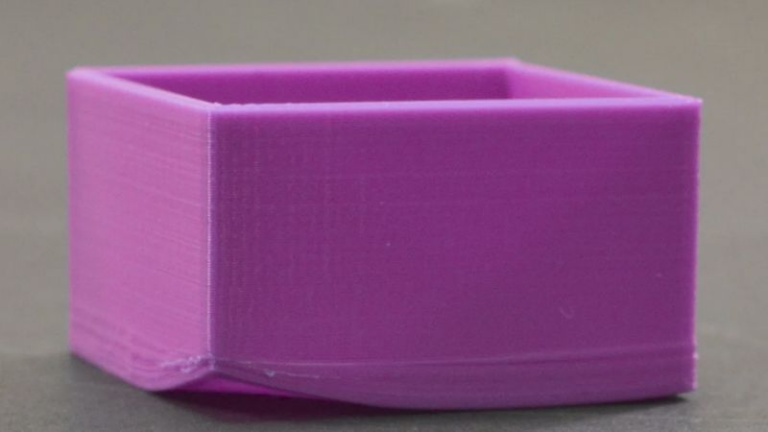

3D Print Vs. Injection Molding

Injection molding and 3D printing are two manufacturing processes widely used today. While both technologies…

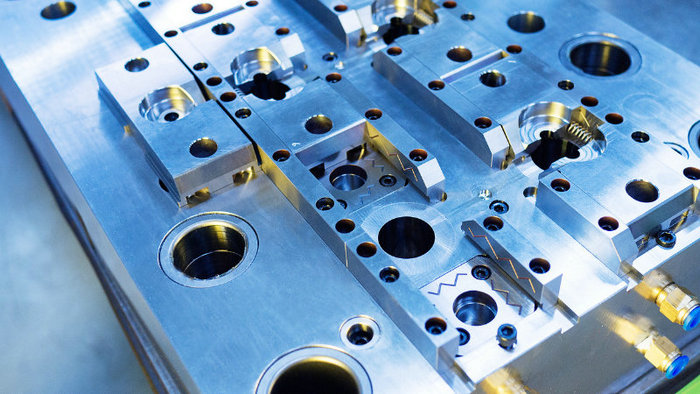

Plastic Injection Mold Design: Essential Tips for Success

Plastic injection molding is a widely used manufacturing process that is both cost-effective and versatile…

Injection Molded Parts

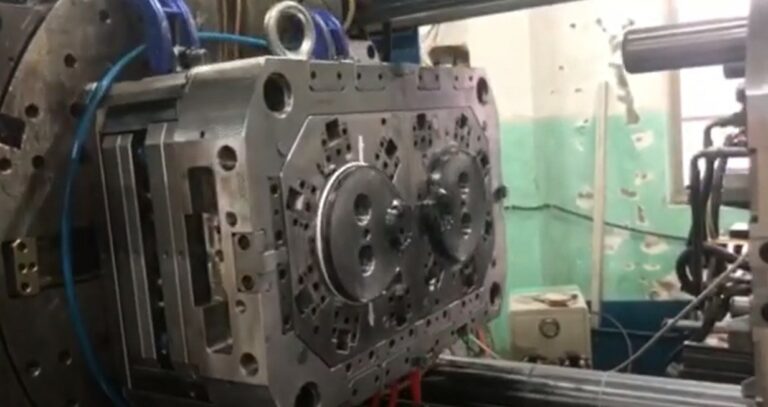

The injection molding technique is used in manufacturing injection molds for identical parts, known as…

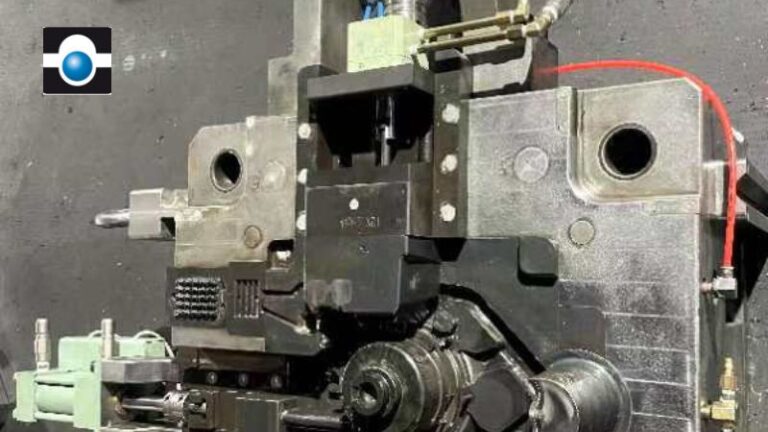

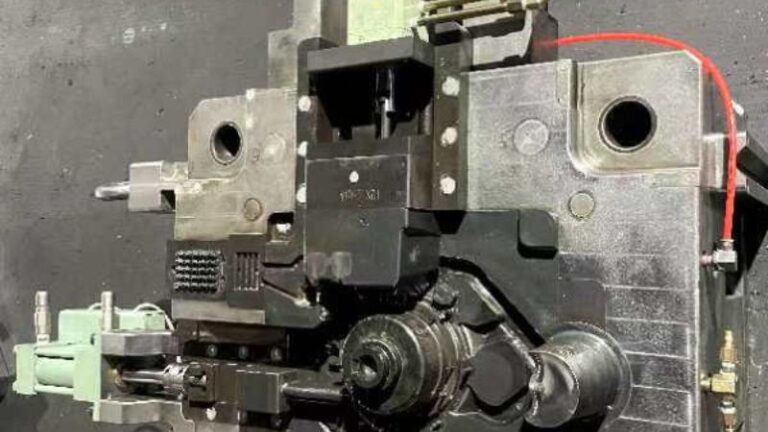

Injection Molding Tools

Plastic injection molding or injection molding is the production of plastic parts in large quantities…

Two Shot Molding

Two different plastic resins are molded together in a single machining cycle during the double…

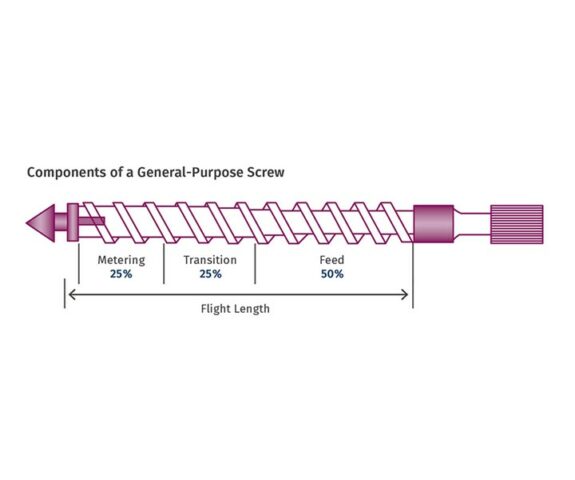

What is shot size in injection molding?

The largest amount of plastic injection mold that may be injected during a molding cycle…

What Is PP Material?

Polypropylene (PP) is one of the most popular plastic materials used worldwide. It’s a semi-crystalline,…

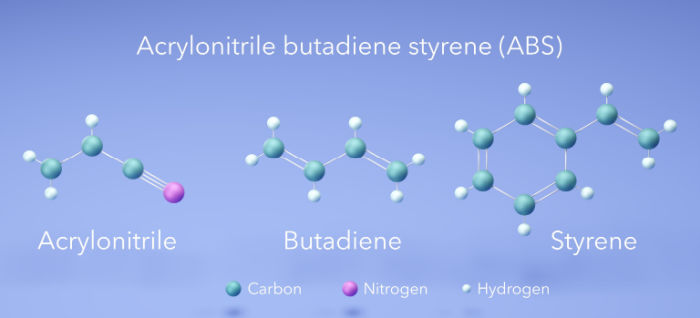

What is ABS injection molding?

ABS stands for Acrylonitrile Butadiene Styrene. It’s a type of thermoplastic polymer with three major…

How much does custom injection molding cost?

Injection molding, also known as plastic injection molding, refers to large production volumes of plastic…

Application Of Automotive Injection Molding

Plastic injection molding continues to advance with the emergence of new technology. With the rapid…

Everything You Need To Know About The Tesla Cybertruck

The Tesla Cybertruck may look like the ugliest pick-up truck you’ve ever seen, but that…

12 Strangely Interesting Facts About How Our Plastic Food Containers Are Made

The primary function of plastic food packaging is to protect contents and guarantee the health…

Types of Injection Molding Gate

To get the best results for your molding projects, it is essential to choose the…

Parting Line Injection Molding

We already know that injection molding is a highly complex process. It requires deep expertise…

Stack Molding: Everything You Should Know

There is a high demand for plastic products, and sometimes it can be challenging to…

All About the Injection Molding Valve Gate

The injection molding machine performs its functions properly because it features many components. These components…

Using Recycled Plastic for Injection Molding

Every stakeholder in the manufacturing industry has a responsibility to protect the environment. This responsibility…

Reverse Injection Molding Process

The reverse injection molding has made the plastic formation process more efficient in many ways.…

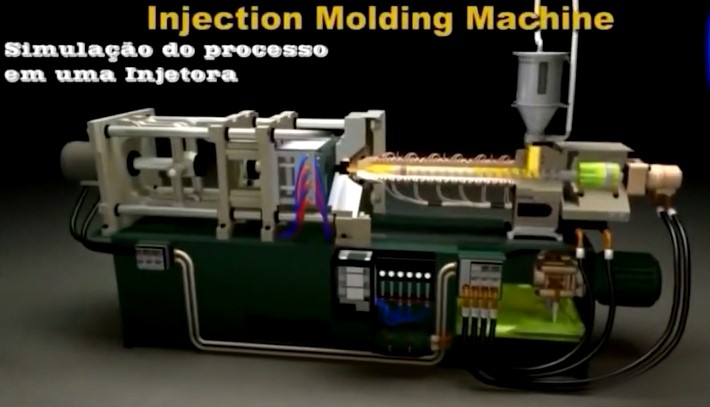

3D Video for the plastic injection molding process

Here is 3D video for the plastic injection molding process. From feeding to demoulding, you…

Plastic Injection Molds Trial Production for Lamborghini

Moldie manufactured molds of Lamborghini auto parts as you can see in this video that…

Injection Molding Threads

Many people wonder about the possibility of molding a thread by using the injection molding…

Benefits of PMMA Injection Molding

Polymethyl methacrylate (PMMA) injection molding is a process that involves injecting organic glass and acrylic…

Injection Mold Texturing – Important Things to Consider

We come across various plastic or metal parts with different looks, designs, and textures every…

How the Injection Mold Slide Works

The injection molding process is one of the best ways to produce plastic products in…

The Injection Mold Lifter – Overview

The main industrial processes in the plastic industry have been enhanced since the introduction of…

Is Polystyrene Injection Molding a Good Idea?

The short answer to the question above is yes. Polystyrene is one of the polymers…

What to Consider for Injection Molding Polyethylene

One of the best materials for injection molding is polyethylene. However, there are some differences…

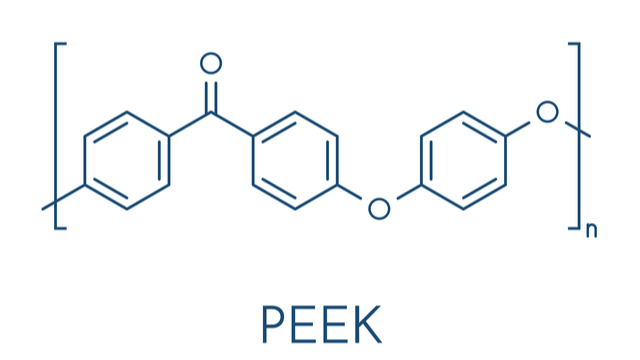

How You Can Avoid Issues During PEEK Injection Molding

To begin with, we should explain what PEEK means. It is an abbreviation that stands…

What are Plastic Injection Mold Components?

Looking at a coupled injection molding machine for plastics, you can hardly guess the number…

Tips to Prevent Sink Marks During Injection Molding

Plastic production is a unique process. You can get impressive production results from your factory…

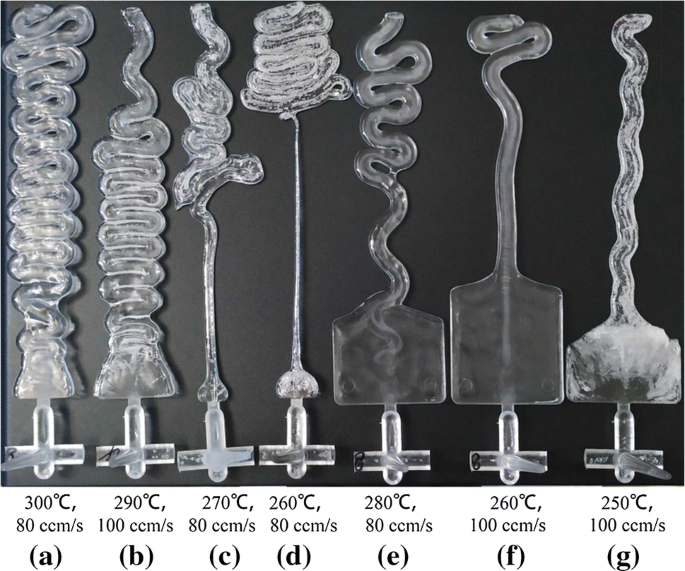

How to Avoid Injection Molding Jetting and Get Better Results

There have been too many arguments about the best ways to prevent jetting during injection…

Flow Mark in Injection Molding: Causes and Solutions

What is flow mark in injection molding? A flow mark is commonly referred to as…

Things To Know About Backpressure Injection Molding

During the injection molding process, back pressure is applied from the backside of the screw…

What are the Advantages of Injection Molded Fiberglass?

When you hear engineers talking about injection-molded fiberglass, they refer to products made by infusing…

Which Products are made by Precision Injection Molding?

Have you been wondering about the products made by precision injection? We have found a…