Mold Design & Engineering

Mold Design Service

Request a Quote

Process of Plastic Injection Mold Design

Product Analysis

After receiving 2D/3D part drawings from our customers, our engineers analyze the part’s structure to get an initial idea of the mold structure. This is usually done with Design for Manufacturing (DFM).

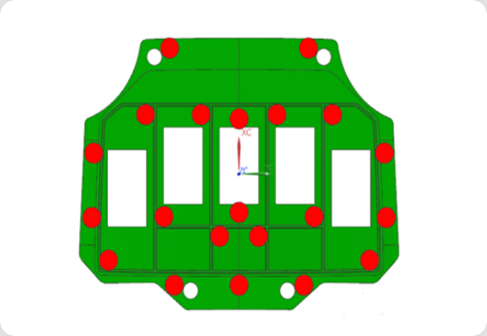

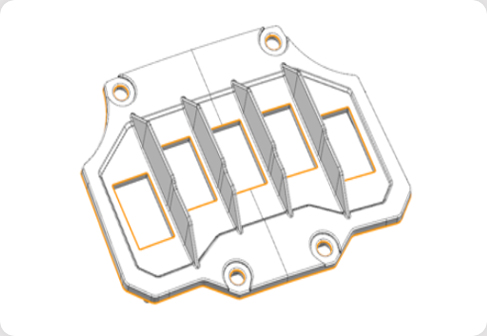

DFM and Moldflow Analysis

Before the plastic injection mold design, we conduct detailed Design for Manufacturing (DFM) and Moldflow Analysis to define the mold’s parting line, sliders, lifters, ejectors, draft angles, injection gates, runners, and other related information. We discuss this phase with our customers to check if the part needs any optimization for feasibility and to reach an agreement on how the mold will be designed.

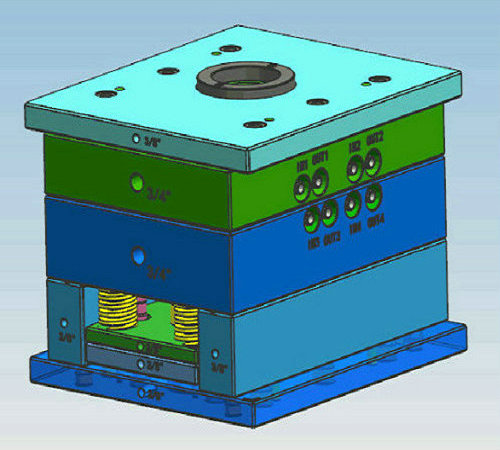

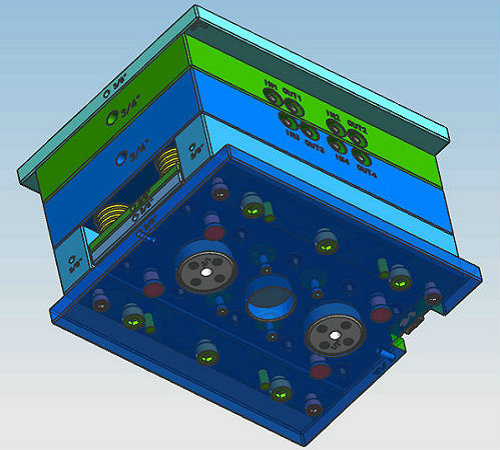

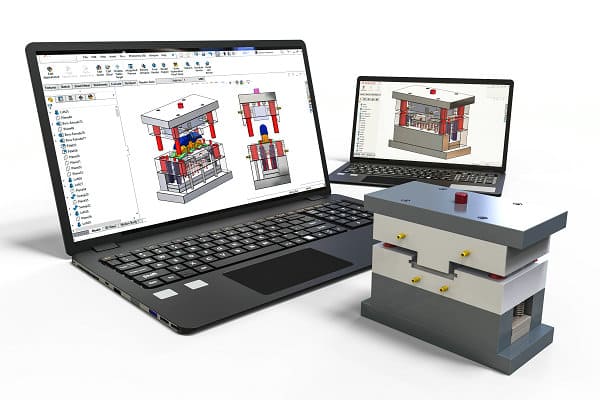

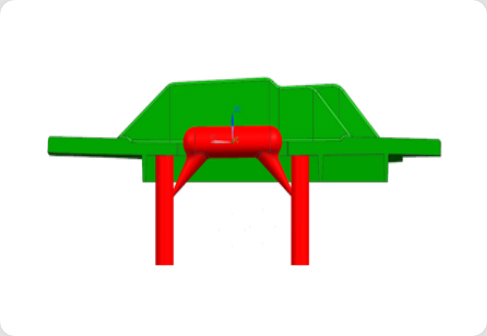

Mold design

After the DFM is confirmed, we start the plastic injection mold design according to the DFM and the customer’s mold specification. Generally, it takes one to two workdays to finish the mold design, and the mold design needs to be approved by our customer mold construction work.