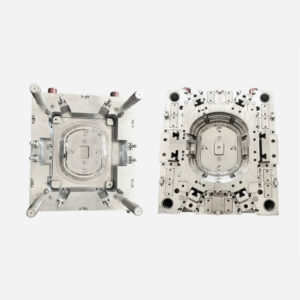

Plastic Injection Mold

Automotive Plastic Injection Molding Companies

Large Plastic Injection Molding Factory

Multi Shot Injection Molding Manufacturing Companies

Custom Plastic Molding Manufacturer

Custom Plastic Injection Molding Service China

Custom Made High Precision Plastic Parts

2 Shot Plastic Injection Molding

Precision Plastic Mould Products Injection Mold

Short Run Hard Shrinkage Plastic Injection Molding Manufacturers

PPE Molding: Draft Angle Plastic Injection Molding

High Volume Plastic Injection Molding Inc

Polycarbonate Plastic Injection Mold Makers

Nylon Molding Manufacturing Company

Complex Plastic Injection Molding China

ABS Plastic Injection Molding Process

Pom Plastic Injection Molding Products

Chinese Large Recycled Plastic Injection Molding Companies

High Quality ABS House Appliance Casing Plastic Injection Molding Price

Medical Plastic Injection Molding Parts Companies

Rapid Plastic Prototype Manufacturing

Request a Quote

Precision Plastic Injection Molds Made to Your Exact Specifications

Moldie specializes in the design and manufacture of high-quality plastic injection molds for customers across industries. With decades of experience, our expert mold makers utilize advanced manufacturing processes to produce molds that meet your exact specifications.

Custom Plastic Injection Molds for Flawless Molding

Our plastic mold-making process begins with a detailed design phase using precision CAD software. We analyze your product requirements and specifications to design molds with the optimal configuration for your application.

Key design considerations include:

- Number of cavities

- Runner and cooling systems

- Draft angles and ejector pins

- Surface finishes

- Clamping force and injection pressure

- Resins and materials

We use CNC machining centers, EDM, and grinding to fabricate molds from metals like P20 steel with exceptional structural integrity and durability. Our quality control procedures ensure each completed mold meets predetermined tolerances and is capable of repeatable, high-quality production runs.

Prototyping, Sampling, and Low to High Volume Production

We offer comprehensive support throughout the injection molding process. Our in-house services include:

- Prototyping and sampling with 3D printing

- Small test runs to confirm mold performance

- Volume production of thousands to millions of parts

- Part assembly and secondary processing

- Ongoing mold maintenance and repair

Trust Our Plastic Injection Molding Experts

With experience across a diverse range of industries including automotive, medical, and consumer products, Moldie has the expertise to deliver high-quality, precision plastic molds tailored to your application. Contact us today to get started designing and manufacturing your custom plastic injection molds.