Precision Plastic Parts

The best manufacturing process involves using excellently designed precision plastic parts. These parts are made with complex geometries and machining tools that correctly get the dimensions, color, and other features. The complexity of the primary and secondary and finishing operations involved is why you should only hire the services of experts like those in our company to handle your production process.

We understand all about injection molding and the advantages of precision injection molding. Our team has been trained to use their knowledge, without reserve, to ensure every client who buys bulk precision plastic parts from us is satisfied with their results.

What Efforts Go into Making Precision Plastic Parts?

There is much to consider when using sophisticated tools to manipulate and reshape plastic material, like those used for making precision plastic parts. Then, the entire process must be done with extreme care because the final product must have tight tolerances. We consider the molding process, machining tools grade, the injection molder, CNC machining, and the molding cycle, to mention a few.

The precision molding process may seem quite complicated to people new to the game, but for us, it is easy. These plastic parts, like the plastic optic lenses and other high-precision metal parts, are removed from the final product that comes from the machining tool.

Industries Demanding Precision Plastic Parts

If you are interested in investing in buying and reselling these precision plastic parts, it is a great time to start. Join hundreds of investors buying these products in bulk or supplying the materials we need to achieve all production goals.

We have maintained an excellent workforce that cannot fail when delivering the best results. Therefore, you should buy these precision components from us in bulk and join others who enjoy using our outstanding services.

Here are some of the industries you should consider supplying because there is an unending demand for the precision plastic parts in them:

The medical industry is one of the sectors needing precision molding products for several medical devices. Also, the military needs these parts for their devices. Plastic parts are also essential in the automotive industry and other industries where the workers do a wide range of highly technical process operations.

We have the resources to consistently deliver plastic injection molding parts for primary and secondary operations in several industries.

How to Order from Us

It is so easy to order precision plastic components from our company. All you need to do is send us your customer contact form to order. We will respond and provide all necessary guidance to help you get your goods quickly.

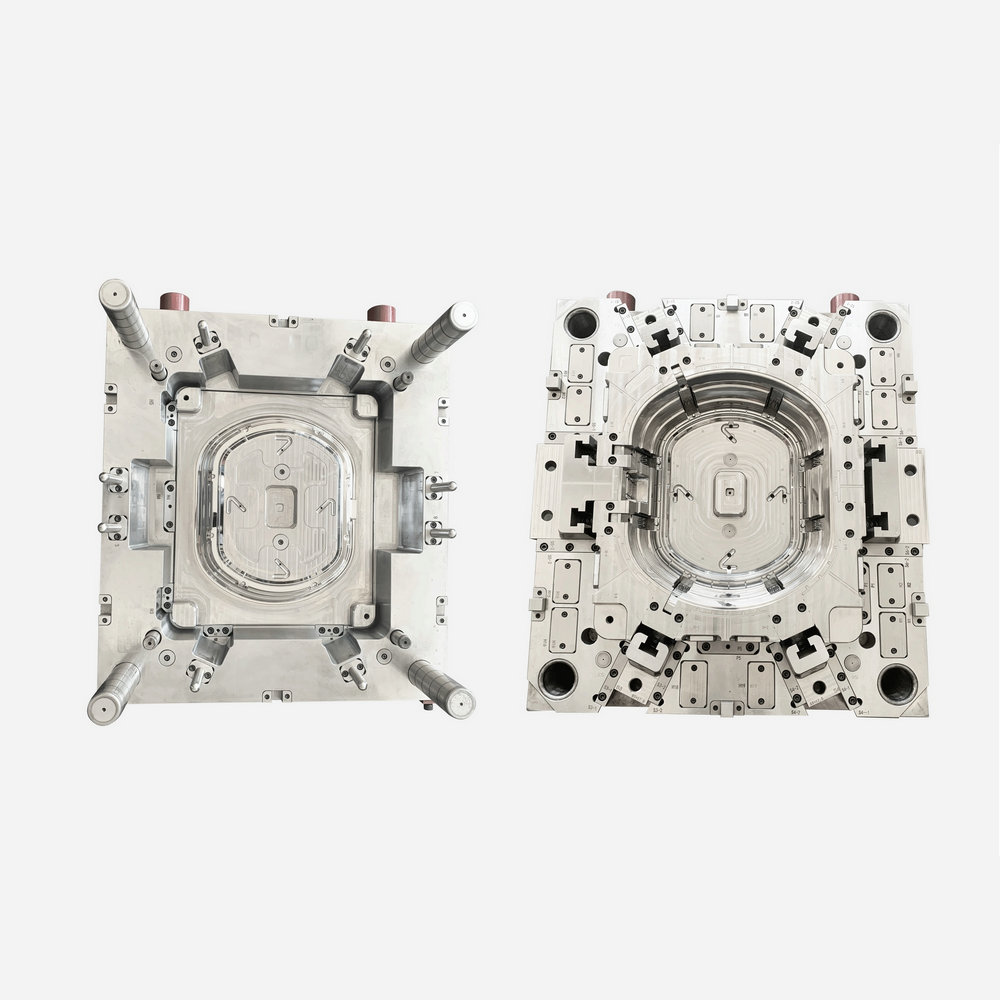

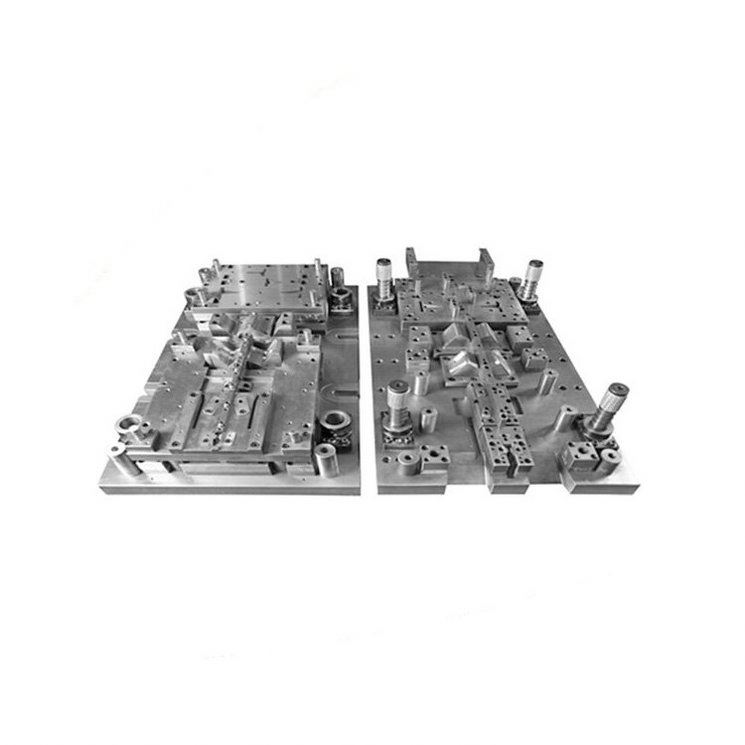

Product Description – High Precision Injection Molding Parts

These products have drawn countless positive reviews from the public because they are excellent. The precision molding plastic parts are also easy to use and durable. Here are the main features:

Mold Materials

These precision plastic components result from injection molding done by experts with lots of expertise. The mold materials for these products include high precision grades like 45#, P20, H13, 718, 1.2344, 1.2738, and any other option most suitable for the particular product you order.

The mold materials have the best quality making the final products part of innovative solutions in many manufacturing industries.

Design Standard

These plastic injection molding parts fall under design category standards like HASCO, DME, MISUMI, PUNCH, and other impressive standards commonly needed in the manufacturing industries.

Product Material Options

Since the products needed in industries vary, we have provided options for the product materials. You can order plastic parts made of PC/ABS, ABS, PC, PVC, PA66, POM, and other options to meet your specific market demands.

Excellent Mold Bases

We ensure the mold design and base feature only the best materials, such as LKM, HASCO, DME, or any other standard you require for custom projects.

Multiple Gate Preferences

These are the best precision components because we have the best tools to maintain production even when you need gate types like the side gate, sub gate, pin point gate, edge gate, etc.

Injection Machine Type

The injection molding machine’s weight range falls between 80 to 1500 tons, which is compatible with a mold weight of 50 kg to 15 tons.

Finally, the standard for product appearance for graining is MT (Mold Tech), YS, HN Series, and the Ral Pantone colored plastic parts are ISO 9001:2015 and SGS certified.

Order in Bulk

Send us your customer contact form to order these precision molding plastic parts today. We have excellent customer service and no delivery delays.