PPE Molding

A lot of research has gone into developing the injection molding machine, and we have invested in the best of them. Our goal is to become a brand that consistently provides products from injection molding that stand out in the market and impresses our clients. For those who need to know what to look out for when ordering ppe molding products in bulk, we encourage them to buy from us because our staff can provide all the guidance they need, guaranteeing satisfaction.

The plastic injection molding machine consists of several parts that require elaborate expertise to monitor and manage while using the injection molding machines. The whole idea of using these plastic injection machines is to reshape molten plastic, which is the raw material, into something unique.

There is a global demand for these products of the injection molding process, so it is a great time to invest and start earning money from a business that continues to grow significantly.

The PPE Plastic Injection Molding Machine Manufacturing Process

When it comes to PPE molding, everything happens under high pressure in a controlled environment where the injection moulding machine converts the raw materials, which can be plastic pellets, or plastic granules, into well-defined products with varying dimensions and features.

After preparing the plastic pellets, they are fed into the injection moulding machines correctly, and the machine injects the raw materials into the molds in their molten state. This is where the production occurs and the ppe molding product is formed. Then, the mold is removed and cooled. After that, the product is ejected for processing and packaging. The high pressure production process is created to ensure the final product is perfect, according to the production brief.

The goal is always to produce products that clients will be satisfied with because the ppe plastic parts are used in so many industries worldwide.

Parts of the Injection Molding Machines

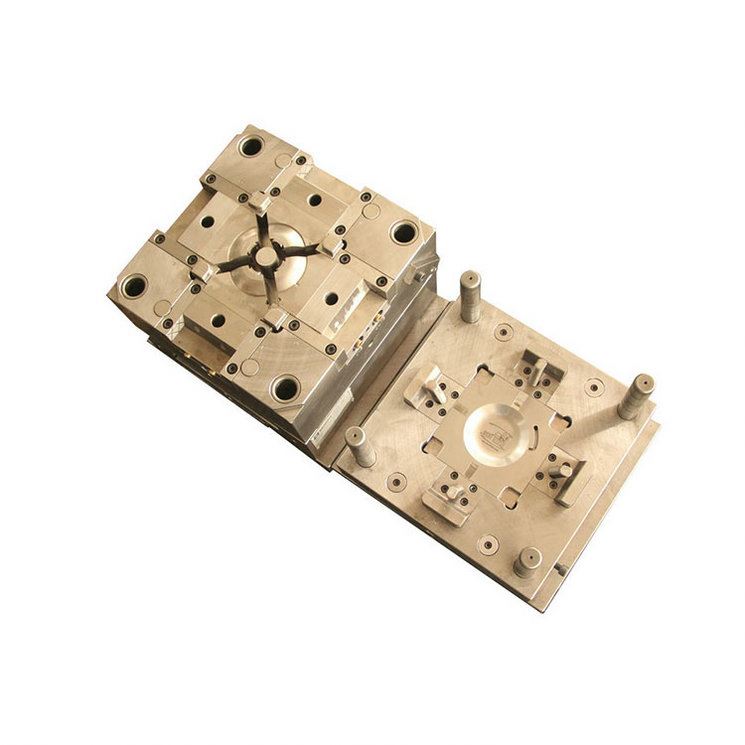

Different parts work together to give the outstanding ppe molding products we sell. These parts are assembled in the majestic injection molding machine. The injection molding machine consists of the following components:

- The Barrel – This is the part where most of the high pressure activity happens. The barrel contains a heating element that converts the raw materials into molten plastic. The heated barrel must be large enough to contain the raw materials to prevent spills.

- The Hopper – This is like the purifying unit that removes anything that could ruin the final plastic parts. There is a magnet and a drying chamber that ensures no trace of moisture during production.

- The Clamping Unit – This is where the injected plastic is reshaped in a mold or cavity. The clamping unit opens up to eject the formed plastic part after cooling.

- The Base – This part holds the entire injection molding machine together. It is a sturdy base and must be on a flat surface.

Product Description – PPE Molding Products

These products have general features that make them stand out. We have written about these features to enable you to understand what you will get as ppe plastic parts:

The Mold Base

The features of this base are flexible and done according to the project requirements. For example, you can order ppe molding products with an LKM, HASCO, or DME mold base.

Mold Materials

The mold materials used to make the ppe products can be in the 45#, P20, H13, 718, 1.2344, or 1.2738 production rating. The choice depends on the type of parts you want to order.

Production Standard

Our production team can make products in standard categories such as – HASCO, DME, MISUMI, and PUNCH. We are flexible and ready to adjust the methods to meet your market’s needs.

Gate Type

Typically, the production system with the injection molding machine supports the hot or cold runner system, which is very convenient. Also, the gate type for the injection molding machine includes the side gate, sub gate, pin point gate, and edge gate. We go the extra mile to discuss the options with clients who may need help deciding on the best gate type for their project.

Production Weight Analysis

The injection molding machine can handle from 80 to 1500 tons, and the mold weight can be from 50 kg to 15 tons. These ranges are essential for producing plastic parts that meet the standard for product appearance for graining, like the MT (Mold Tech), YS, and HN Series.

Finally, all products of this entire ppe molding process are ISO 9001:2015, SGS certified.

How to Order in Bulk

We will gladly handle the production of high-grade, durable ppe molded products for your market. You can place an order by sending us your customer contact form. We will respond and guide you on how to proceed with your order.

We ensure excellent customer experience every time and guarantee fast delivery.