Plastic requires different technicalities in its manufacturing process. Plastic injection molding is used to manufacture solid components. This process involves injecting molten plastic into a metal mold to produce plastic parts.

This process can be traced to 1872 when John Wesley Hyatt, an American inventor, patented the first plastic injection molding machine. He was trying to replace ivory billiard balls with plastic balls. His products did not meet the needs of the consumers, however, the machine did.

Consequently, the plastic injection mold-making industry evolved quickly. Today, it is known for manufacturing plastic products on a large scale, including medical equipment.

What Products are Made from Injection Molding

Many manufacturers around the world use injection molding to mass-produce various goods. Injection molding can make large objects like plastic garbage bins and smaller objects for instance, plastic bottles.

Plastic injection molding is also used to make non-consumer parts, especially when visual appeal doesn’t matter. The process of injection molding often leaves impurities on the plastic parts.

Injection Molding Steps

The injection molding process can be broken into four simple steps

●Melt material

●Inject molten material into a mold

●Allow the molten material to cool until it forms a solid-state

●Remove the solid material from the mold.

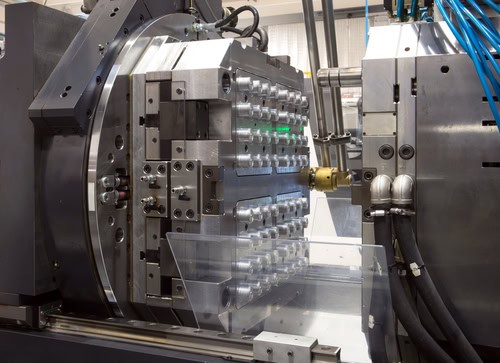

How the Plastic Injection Molding Machine Works

It’s impossible to talk about the injection molding process without talking about the plastic injection molding machine. It has four main parts:

1.Injection unit

2.Clamping unit

3.Control

4.Base

To start the injection molding process, plastic pellets are placed into a barrel that contains an internal auger using a hopper. The auger, a screw-shaped device, feeds materials by rotating. The heater bands melt the plastic into a molten state. At the start of the machine cycle, the drill operating under high-pressure plunges in a syringe into the empty part of the mold called the cavity.

Sometimes, a coolant is used to quickly cool the molten plastic. The coolant, usually water, flows around the mold through channels. In less than a minute, the plastic solidifies, taking the shape of the cavity. Once the plastic solidifies, the mold opens, and plastic is ejected. This process starts again and continues until the job is complete..

What Plastic is Used for Injection Molding

Thermoplastics are commonly used for injection molding. These polymers turn molten under extreme temperatures and solidify under cool temperatures.

The best feature of thermoplastic is that it can be reheated multiple times before it becomes unusable, unlike the thermoset plastic that burns when reheated. Some popular thermoplastics include:

Acrylonitrile Butadiene Styrene (ABS)

It is one of the most widely used materials for plastic injection molding. The rigid and lightweight nature makes it a popular choice for many products, including LEGO.

Polycarbonates

These transparent thermoplastics can withstand high levels of plastic deformation without showing any signs of damage. This thermoplastic is ideal for medical and mobile devices, eyewear lenses, etc.

Nylon

It is also widely used due to its unique electrical properties and toughness. Nylon is used in the production of industrial components.

Polypropylene

It has a high chemical resistance and does not get into food products. This makes this flexible material an ideal choice for food containers or eating utensils.

Polyethylene

This versatile plastic used for injection molding has high impact resistance, recyclability, and low moisture absorption. It is an excellent choice for bags and plastic containers.

Benefits of Plastic Injection Molding

High Efficiency

Plastic injection molding is the most effective form of molding. It is fast and gives a high production output rate that makes it cost-effective for manufacturers.

The speed varies depending on the complexity and size of the mold. However, within a short time, a large quantity of molds can be produced. Low-cost production also creates savings for the customer.

Mass Production

Plastic injection molding is a fast production. This makes it cost-effective and means more volume can be produced within a short time.

Complex Part Design

One of the advantages of injection molding is its ability to handle complex design while maintaining uniformity. However, the designed part must be developed to maximize the efficiency of high-volume molding.

Flexibility Material and Color

With plastic injection molding, the possibilities are endless when choosing the right material and color for a project. To get the best from various materials and colors, it is important to work with an injection molder who has experience with a variety of resins and applications.

Reduced Waste

A good injection molding company will have green manufacturing initiatives. Excess plastic generated during the process of injection molding can be recycled. Use a company with modem machinery to assist in minimizing waste, transporting, and packaging.

Ability to Use Multiple Types of Plastic

Many times, there may be complex designs that require different plastic materials. With plastic injection molding, you can safely combine plastics after verifying compatibility.

Low Labor Costs

A big advantage of plastic injection molding is that labor costs are relatively lower compared with other types of molding.The molding process typically requires minimal supervision with self-gating and automatic tools to keep the operation ongoing.

Why it is Important to Work With an Experienced Injection Molder

To fully enjoy the benefits of plastic injection molding, manufacturers need to find experienced injection molders. They can effectively produce any design following the necessary quality and safety requirements.

The best technology, materials, and equipment are not enough until you get a qualified molding engineer. Here are a few questions you can ask an injection molder if you want to work with the best.

●Do you have experience manufacturing for my industry or products?

●Do you have tools for designing and maintenance capabilities?

●Do you have engineering expertise in molding?

When a molder can confidently answer these questions in the affirmative, you can rest assured you will get the best delivery. We make high-quality plastics for different industries. Our top priority is to ensure all products comply with safety regulatory bodies. Visit our website for more information or to place an order.