With mold bases tailored to your preferences, including options like LKM, HASCO, and DME, the custom plastic parts manufacturing caters to every specific need.

You will dive deep into the world of durability with our range of mold materials, featuring the likes of 45#, P20, and the resilient 1.2738.

Adherence to industry standards is paramount, and with our commitment to the HASCO, DME, and MISUMI benchmarks, quality is never compromised.

Our array of product materials, from PC/ABS to the adaptable PA66, is designed to deliver precision. The finesse of the cold/hot runner system, combined with an assortment of gate types from side to edge, ensures impeccable molding.

Whether it’s a mold weighing 50kg or a substantial 15 tons, they find a perfect match in our versatile injection machines, capable of handling up to 1500 tons.

Furthermore, with the assurance of ISO 9001:2015 and SGS certifications, your trust in our craftsmanship is fortified. Consequently, contact us today and invest in this custom plastic parts manufacturing.

Trade information:

| MOQ | 1 set |

| Mold lead time | T1 sample, about 3-10 weeks, according to the mold requirement |

| Production lead time | 2-5 weeks, according to the order Qty |

| Mold payment term | 50% T/T deposit with PO, balance 50% T/T after sample approved |

| Products payment term | 30% T/T deposit with PO, balance 70% T/T before shipment |

| Port of loading | Ningbo or Shanghai port also can be Shenzhen port |

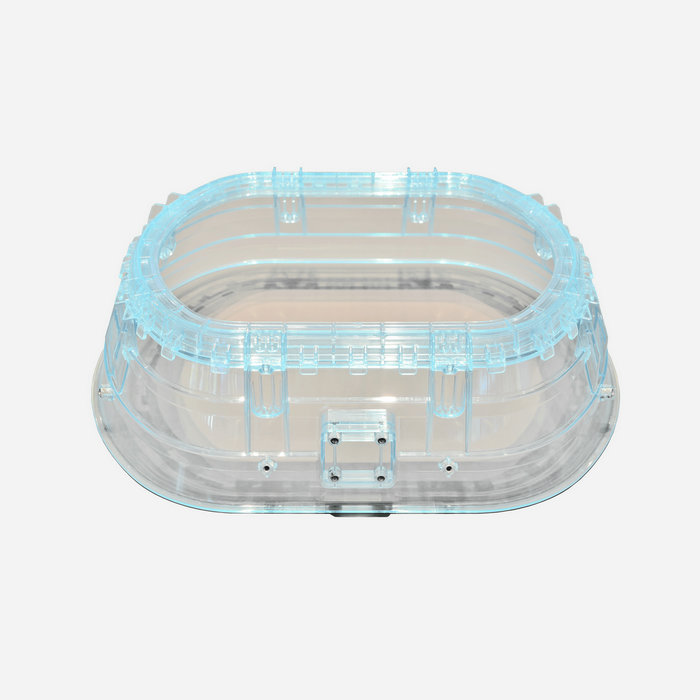

Some pictures of our plastic injection parts:

|

|

|

|

|

|