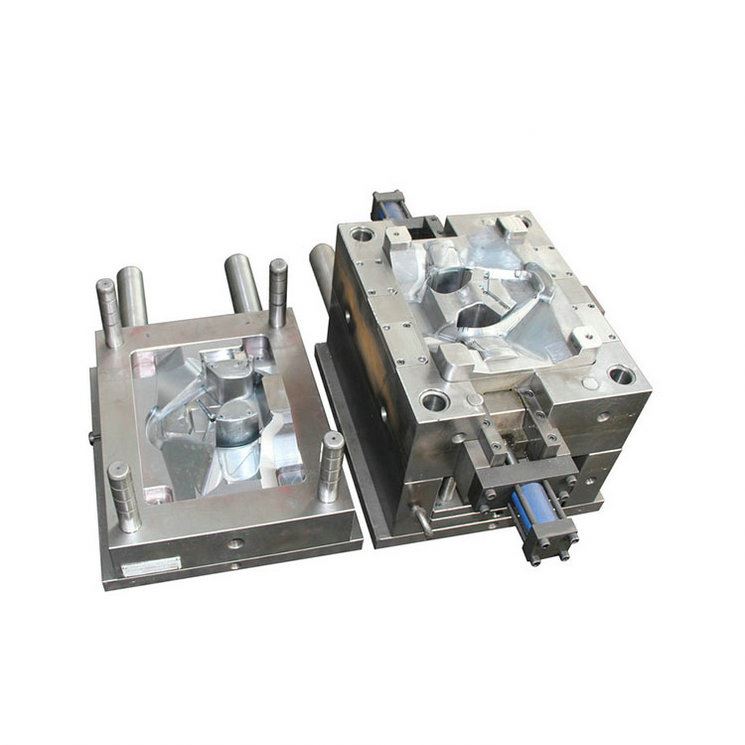

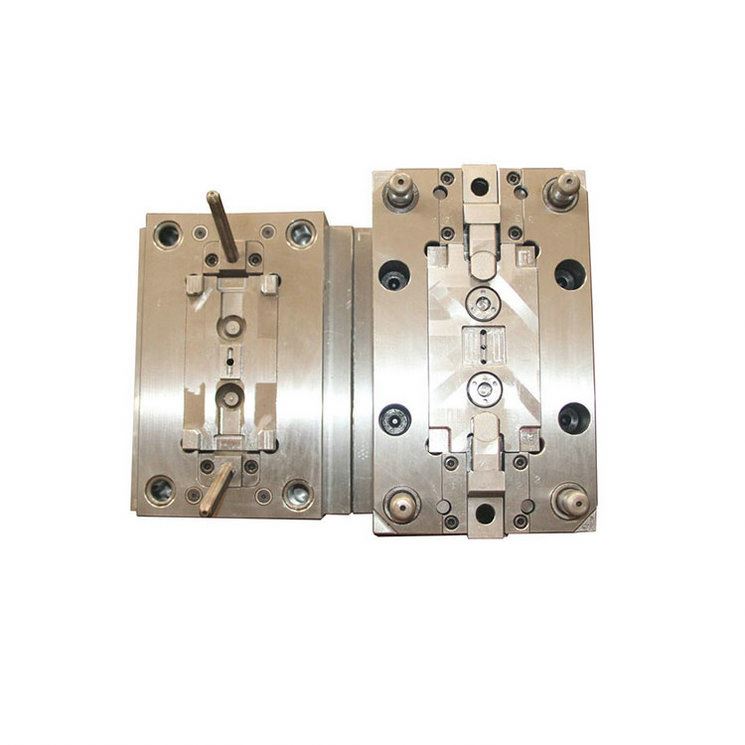

This ABS plastic injection molding process offers unparalleled versatility. The mold base, compatible with LKM, HASCO, DME, or tailored to your specifications, provides the foundation.

We use elite mold materials like 45#, P20, H13, and others to ensure durability. We strictly follow industry standards, including HASCO, DME, MISUMI, and PUNCH, emphasizing top-tier execution.

Besides, you can choose from various product materials, such as PC/ABS, PVC, and PA66, allowing you to customize the mold according to your needs.

The process features both cold and hot runner systems, and you’ll have access to various gate types, from side gates to edge gates.

The molds we offer vary in weight from 50kg to 15 tons and are compatible with injection machines ranging from 80-1500 tons. And they hold ISO 9001:2015 and SGS certifications.

In short, contact us today and experience our ABS plastic injection molding process.

Trade information:

| MOQ | 1 set |

| Mold lead time | T1 sample, about 3-10 weeks, according to the mold requirement |

| Production lead time | 2-5 weeks, according to the order Qty |

| Mold payment term | 50% T/T deposit with PO, balance 50% T/T after sample approved |

| Products payment term | 30% T/T deposit with PO, balance 70% T/T before shipment |

| Port of loading | Ningbo or Shanghai port, also can be Shenzhen port |