Plastic injection molding started in the late 1800s as a way to create precise plastic parts fast and efficiently. This process created the plastic industry and changed how everyday items like toys, containers, and car parts were made.

In this blog, you will learn about the history of plastic injection molding, which helps you understand how it shapes the world around you and why it’s so widely used.

Pioneers and Early Innovators

Early work in the plastic injection molding industry shaped the future of plastic material. Key individuals and industry changes led to new machines, better materials, and growing use in products.

John and Isaiah Hyatt’s Invention

Plastic injection molding dates back to when John Wesley Hyatt and his brother Isaiah Hyatt invented the first molding machine in 1872. Their machine used a plunger to force hot celluloid into a mold. This was the first time plastic parts could be made in large numbers on a daily basis.

The Hyatt brothers are commissioned by a billiard ball manufacturer seeking an alternative to ivory, because the fall in the elephant population was driving up the costs for ivory products. While their celluloid billiard balls were not a perfect successor, as they tended to explode with a loud crack upon heavy impact, they still demonstrated the potential of synthetic materials.

The brothers’ first machine was relatively simple. It consisted of a heated cylinder, a plunger that was often operated by a hand lever, and a clamp to hold the two-part mold closed. The process was labor-intensive and the heating was uneven, but it was a revolutionary starting point. Then, they move on to make buttons, combs, and other small objects. The Hyatts’ machine set the standard for the early plastic production process.

Advancement by Hyatt Brothers

Recognizing the limitations of their initial design, John Wesley Hyatt continued to innovate. He developed and patented a multi-cavity mold, which allowed for the simultaneous production of multiple identical parts in a single cycle, drastically improving output. He also experimented with different cooling methods to reduce cycle times. These revolutionizing improvements were crucial for convincing manufacturers of the commercial viability of injection molding.

The Hyatt brothers’ company prospered, producing not only billiard balls but also a wide array of celluloid products, from dental plates and piano keys to shirt collars and cuffs, which were notoriously flammable but immensely popular.

Development in the Plastics Manufacturing Industry

By the late 1800s and early 1900s, other inventors and companies began using and improving on the Hyatt brothers’ machine. Industries saw the benefits of plastic parts, like low cost and the ability to create new shapes.

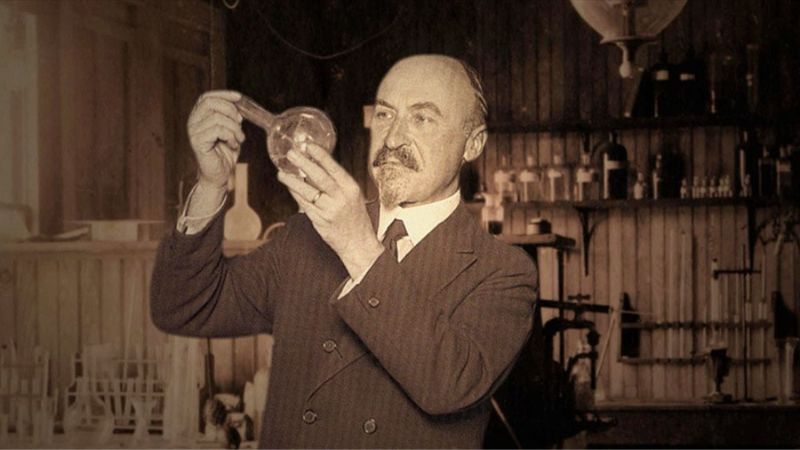

A pivotal moment came in 1909 with the invention of Bakelite by Leo Baekeland. This was the first true synthetic plastic that contains no molecules found in nature. Bakelite was a thermoset material, meaning it hardened permanently when heated, and it possessed excellent electrical non-conductivity and heat resistance. Baekeland also invented a special injection molding machine to process his new material. The patent for his “Bakelizer” machine and the material itself opened up entirely new markets, particularly in the rapidly growing electrical and automotive industries for components like distributor caps, radio cabinets, and telephone housings.

The 1920s and 1930s saw the development of new thermoplastic materials, such as polystyrene and polyvinyl chloride (PVC), which could be repeatedly melted and reshaped. This made recycling scrap plastic directly in the factory a possibility. Around the same time, soluble forms of cellulose acetate for plastic injection, such as Cellit and Cellon, were developed by Arthur Eichengrün in 1903 and 1939 respectively, offering a less flammable and injection-moldable powder form of the plastic.

During this period, German chemists at BASF also began pioneering the use of screw extruders for plasticizing materials, a concept that would later be critical for the injection molding manufacturing process. While plunger machines remained dominant, the stage was being set for a major technological leap. The demand for inexpensive, mass-produced consumer goods during the interwar period fueled the construction of larger, more automated plunger machines, though they still struggled with controls over the injection temperature and consistency of the molten plastic.

As technology advanced, machines could produce larger parts with higher precision. This allowed consumers to find plastic products in more places, from cars to electronics. The spread of injection molding made plastic manufacturing and injection molding services much more common by the mid-1900s.

Expansion During World War II

During World War II, plastic injection molding quickly became an essential process. We can observe major advances in materials and manufacturing methods that support the war.

Material Innovation for Mass Production

The war effort significantly boosted the demands for new materials with specific properties. Nylon, invented just before the war, was rapidly diverted from its intended use in stockings to become a critical material for parachutes, ropes, and bearings. Acrylics provided a shatter-resistant alternative to glass for aircraft canopies. Polyethylene, discovered accidentally by British chemists in the 1930s, became indispensable as an insulating material for radar cables, giving Allied forces a significant technological advantage.

The injection molding process was perfectly suited to mass-produce thousands of these essential components with the required consistency and speed. This period forced an unprecedented acceleration in polymer science and the rapid expansion of plastic production.

The precision of injection-molded parts proved vital for complex military equipment. For example, proximity fuses in artillery shells required tiny, perfectly formed plastic components to house their fragile electronic mechanisms. The consistency offered by molding was much superior to other manufacturing methods like machining or compression molding. This era nailed the relationship between the military-industrial complex and the plastics industry, a partnership that would continue to drive innovation for decades to come.

Role in the Manufacturing Industry

The war also led to significant advancements in mold-making techniques. The need for rapid production of new parts necessitated faster and more durable mold creation. This spurred the use of better tool steels and more precise machining processes. Furthermore, because of the intense demands for plastic parts, the concept of “design for manufacturability” became crucial; engineers had to design parts that could be effectively and reliably produced on injection molding machines, considering factors like wall thickness, rib design, and gate placement. This mindset became a permanent part of industrial engineering.

Also, there was a clear shift from metal to plastic as steel shortages grew. Manufacturers rely on the molding process to make parts that fit tight tolerances and have uniform quality. This is vital for things like communication gear and medical devices.

With the war’s end, the massive industrial capacity built for plastic production was redirected toward consumer goods. Manufacturers who had perfected the art of making rugged, reliable plastic parts for the military now applied that expertise to creating affordable products for the home. This led to the “plastic age” of the 1950s and 60s, where injection-molded plastic items—from Tupperware containers and toys to household appliances and furniture—became symbols of modern living.

Modern History Of Plastic Injection Molding

Injection molding machinery has changed a lot over time. Early models used simple designs, but later machines brought new technology that made production faster and more efficient.

From Plunger to Extrusion Screw Injection Machines

The first injection molding machines, invented in the late 1800s, used a plunger system. Plastic pellets were heated until soft, then a plunger pushed the melted plastic into a mold. These machines were simple but had some problems.

The fundamental issue with the plunger was its inability to homogenize the melt. The plastic closest to the heated walls of the cylinder would often overheat and degrade during the injection process, while the material in the center might not be fully melted. This led to parts with visible splay marks, weak structural integrity, and variations in color. To partially address this, some machines incorporated a “torpedo” or “spreader” in the cylinder, which helped direct the flow of plastic against the heated walls, but it was an imperfect solution. The limitations of the plunger machine were the primary bottleneck to achieving higher quality and more complex parts.

A major improvement came with the introduction of the screw injection molding machine. The invention of the reciprocating screw is widely credited to American inventors H. G. De Mattia and James Watson Hendry, who built the first prototypes in the 1940s and 50s. Hendry’s work was particularly influential. His design allowed the screw to perform two functions: first, it would rotate to feed, melt, and homogenize the plastic resin at the front of the barrel (a process called plasticizing). Then, the entire screw would move forward like a plunger to inject the prepared melt into the mold cavity. This reciprocating action was a game-changer. It provided a much more consistent and uniform melt, which directly translated to higher part quality and fewer defects.

Screw injection molding machines made it possible to create more complex plastic components with greater precision and less waste. You could also use a wider variety of plastics.

James Watson Hendry’s Legacy

James Watson Hendry didn’t stop with the reciprocating screw, in fact, he kept his momentum and eventually became one of the leading figures in the plastics molding industry. In the 1970s, he went on to develop the first gas-assisted injection molding process, which allowed for the creation of complex, hollow parts with minimal shrinkage and warpage. By the time he passed away at the age of 94 in 2014, he owned over 80 patents in plastics processing technologies.

This innovation highlighted how machinery evolution was enabling entirely new product designs. Furthermore, the adoption of closed-loop control systems in the latter part of the 20th century brought unprecedented precision to the process. Sensors could now monitor pressure and temperature in real time, making micro-adjustments to the machine’s hydraulics and heaters to maintain perfect consistency throughout a production run.

Another major shift was the development of all-electric injection molding machines. While traditional machines used hydraulic power, which was powerful but prone to leaks, energy inefficiency, and oil temperature variations, all-electric machines used servo motors to control every movement. These electric machines, which became commercially viable in the 1980s and 90s, offered greater precision, quieter operation, cleaner production environments (no hydraulic oil), and significant energy savings—often using up to 60% less power. This made them ideal for high-precision industries like medical device manufacturing.

Future of Plastic Injection Molding

Today, the frontier of injection molding machinery lies in the integration of Industry 4.0 principles. Modern machines are equipped with sophisticated monitoring systems that collect vast amounts of data on every shot. This data can be used for predictive maintenance, quality assurance, and optimizing production efficiency. The future points toward fully connected “smart factories” where injection molding machines autonomously adjust their parameters to compensate for material variations or environmental changes, ensuring perfect part quality with minimal human intervention.

Frequently Asked Questions

Can you describe the different types of plastic injection molding techniques?

You will find several main types of injection molding. Traditional injection molding is the most common method and uses a single cavity mold to produce identical parts.

Overmolding combines two or more materials during the molding process. This method is useful for creating products with soft grips or multiple layers.

Insert molding adds metal or other components into the mold before injecting plastic around them. This process is common for making electronic parts and threaded inserts.

Micro injection molding makes very small, precise components, often for electronics or medical devices. Structural foam molding uses a blowing agent to create parts with a solid shell and foam core.

What are some of the key innovations that have shaped the modern injection molding industry?

Computer-aided design (CAD) and computer-aided manufacturing (CAM) have made mold making more accurate. You can now create molds faster and with fewer errors.

Hot runner systems have replaced cold runners in many factories. This change reduces waste by keeping the plastic molten and ready for the next part.

Electric injection molding machines have replaced some traditional hydraulic machines. These electric machines use less energy and offer more control over the molding process.

Improved sensors and process monitoring technology let you control pressure and temperature more closely. This helps increase quality and lowers defect rates.