Many people wonder about the possibility of molding a thread by using the injection molding machine. It is possible, and the outcome, and products, are always outstanding. The injection molding machine has been used for many processes, and creating molding threads is another excellent application.

What is the molded thread?

In this context, we are talking about the plastic thread that you see on product necks. For example, plastic bottles and containers mostly have threaded necks. It is the thread that holds the plastic caps and other closures firmly. Without a threaded neck on the plastic product, there is no guarantee that the content you want to store inside is secure.

Also, you must make a good thread on the plastic container. This is where the injection molding machine comes in. The best threads for plastic products have a consistent pattern and are well defined. That is how it holds the plastic cap in place.

Is the injection molding thread process complex?

The process depends on many factors. If you can create the right setting, it won’t be such a difficult task. For example, you need to ensure that your injection molding machine is working perfectly. For this part, please never overlook any problems observed while your injection machine functions. All serviceable parts should be checked often. And you should test the machine before using it to make injection molding threads.

The most challenging part of the process is injecting the threads because of their delicate nature. You may encounter more issues if you use the standard knock-out method. And for products with undercuts, the entire process becomes quite complicated. However, experts understand how these things work and can perform injection molding threads processes efficiently.

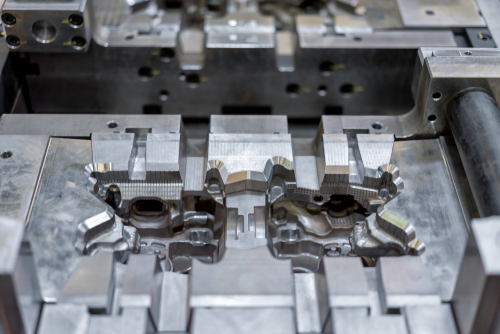

We can also confirm that our outstanding top-of-the-range injection molds are perfect for injection molding threads. If you need to inject a ridge, using our molds guarantees excellent results.

Types of Injection Molding Threads

There are two general types of these threads. These are the external and internal injection molding threads. These are the two standard features that you will find on many molded plastic products.

Also, depending on the client’s order, you can make the external and injection molding internal threads according to the American Standard, the regular buttress thread, or the tapered pipe thread. All these options are excellent, so your choice becomes a matter of preference.

Advantages of using injection molding threads

Generally, people like to avoid the mechanical processes of forming threads on plastic products. The reason for this choice is that it is a longer and more challenging process. Instead, you should focus on the benefits of using the injection molding threads.

The injection molding machine allows you to mold the thread directly on the plastic product. This can be done whether you are forming an external or internal thread. Overall, this is one of the main benefits of using the injection molding machine.

However, always ensure that you use the best mold for the process. Have a look at our range of molds. We sell high-quality and durable molds needed for excellent results.

Other advantages are as follows; you save time because the process works without delays. Also, you can increase customer satisfaction because the products are flawless.

Forming External Threads On Plastic Products

When you need to form an external thread on a plastic product, you can use different methods. However, we should inform you that some options will cost more money than others. For example, if you choose to use an external accessory attached to the mold, you will spend more money purchasing or renting it.

On the other hand, you can easily save your money by focusing on the parting line. All you need to do is create your external thread following the parting line on the thread’s center for this process. As always, you are guaranteed to get better results if you use the right tools and materials. Contact us for the best injection molds.

Forming Internal Threads On Products

The procedure to form an internal thread in a plastic product is quite different. For this process, you will need to use an automated unscrewing machine. This is what you will use to create the partially formed internal thread. While forming the internal thread, please be careful with the measurement gauge to avoid exceeding the mark.

For this process, you can also use a manually operated thread insert device. It is quite easy to use; insert the device to form the thread and remove it when you are done.

Forming Stripped Threads on Plastic Necks

Generally, the stripped threads are rounded. This makes it easy to detach it from the mold after formation. To get it right, you need to use the perfect configuration and ensure that the thickness of the plastic meets the recommended standards.

Forming the Thread Profile

There are different types of thread profiles. We have the buttress and the ACME thread profile. To create these profiles, you should follow the recommended specs for a unified thread standard. The advantage of adhering to the unified thread standard is that you can avoid getting feathered edges on the plastic thread you form.

Generally, you should follow the standard whether you are creating threads in any of the categories. We recommend Class 3A for precision work. However, it requires a complicated molding process, so you should be careful.

Things to Avoid When Forming Threads

Whether you are forming injection molding internal threads or the external type, you will need resources. Therefore, it is essential to do the job perfectly to avoid wasting your precious resources. Some situations to avoid are as follows;

●Do everything you can to follow the right procedure to avoid cross-threading. This can ruin the previously well-formed threads.

●Monitor the process closely to avoid loose ends on the thread,

●Avoid forming corners that are too sharp at the thread’s end.

●Avoid distorted edges at the thread’s tip or root.

To conclude, you can get consistent results if you follow the standard configurations. Therefore, do proper preliminary checks before you start the process.