Acrylic injection molding is a popular method for producing clear, strong, and durable components made from polymethyl methacrylate (PMMA). This thermoplastic material is widely used because of its translucent feature, UV and weather resistance, and stability under various conditions. In this article, you will learn the basics of acrylic injection molding and its various aspects.

Understanding Acrylic

Let’s familiarize ourselves with PMMA. It is a transparent and versatile plastic known for its impact resistance and easy processing. Some common applications of PMMA include mobile phone displays, aquarium screens, and automotive windows. Acrylic (PMMA) injection molding offers numerous advantages, such as excellent optical properties, low cost, and design flexibility.

Functional Properties of Acrylic

Many plastic products we use every day are manufactured with acrylic resin. First of all, let’s talk about the strength aspect of acrylic.

Acrylic exhibits a tensile strength of about 75 MPa, making it relatively strong for a plastic material. When it comes to flexural strength, acrylic performs well with a value of 90 MPa. This means that your finished acrylic parts can withstand reasonable pressures without breaking or getting deformed.

Regarding dimensional stability, you’ll find that acrylic parts produced through injection molding have minimal shrinkage and maintain their original shape even after multiple cycles of heating and cooling. Moreover, the transparency of acrylic is one of its most appealing features. With a light transmission rate of 92%, acrylic is optically clear, making it an ideal choice for lenses, light guides, and other applications where clarity is crucial.

Acrylic is also known for its excellent hardness and scratch resistance. With a Rockwell hardness rating of M100, it’s a reliable material choice for applications that require a decent amount of wear resistance. While its impact resistance may not be as high as other polymers like polycarbonate, acrylic still offers decent protection against impacts, with an impact strength of around 16 kJ/m².

In addition to its mechanical properties, acrylic has good chemical resistance to various solvents and cleaning agents. It means your finished parts will stand up well against chemical degradation over time.

Finally, let’s discuss the flexural modulus of acrylic, which sits at around 3.2 GPa. This indicates that acrylic parts exhibit a suitable level of stiffness, allowing them to retain their shape under heavy loads without getting overly flexible.

Acrylic in Various Elements

One of the essential advantages of acrylic is its clarity and transparency, making it perfect for numerous applications, such as lenses, screens, windows, and signs. When injection molded, acrylic parts are known for their impressive aesthetics and durability. The automotive industry, for example, uses acrylic for windows and taillights, which require both transparency and strength.

In addition to components, acrylic can also be found in the form of paint. That’s because it adheres well to a wide range of surfaces and is water-resistant. If you’re working on projects that require a durable and lightweight paint solution, acrylic might be the way to go.

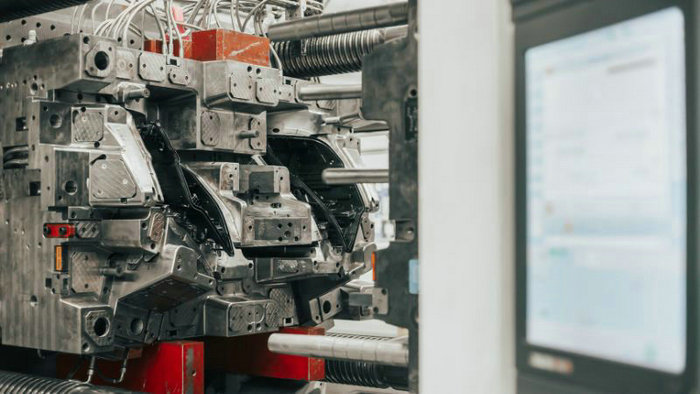

Stages of Acrylic Injection Molding Process

Acrylic injection molding is a popular technique for creating various plastic PMMA components with outstanding aesthetic qualities. In this friendly guide, we will walk you through the main stages of the acrylic injection molding process so that you can better understand how your desired products are made.

- Material Preparation: Before starting the molding process, it’s essential to ensure that the plastic material is prepared correctly. To achieve optimal results, the moisture content should be less than 0.1%, preferably around 0.04%.

- Melting and Injection: Once the materials are prepared, they are fed into a heated barrel where they melt and become molten plastic. The injection speed plays a critical role in determining the final product’s quality. To achieve a flawless finish and reduce defects, injecting the molten plastic at a moderate speed is recommended.

- Cooling and Solidification: After the molten plastic is injected into the mold cavity, it needs time to cool down and solidify. Cooling rates should be carefully controlled to avoid warping, shrinkage, and other defects. The cooling process can be quite delicate, but proper management ensures your acrylic products will have the desired shape and strength.

- Ejection and Part Removal: Once the acrylic component has cooled and solidified, it’s time to carefully eject it from the mold. Remember to use caution when removing the part to avoid damaging its surface or structure.

- Post-processing: Depending on your final product requirements, there may be some additional steps to complete:

- Sanding: If the acrylic part has uneven surfaces or rough edges, gently sanding the material helps to smooth it out.

- Polishing: For a high-gloss finish that enhances the acrylic’s transparency and overall look, polishing is an essential step. You can use polishing compounds or buffing tools to achieve a mirror-like shine

Aesthetics and Finishing

To achieve the desired surface finish for your acrylic parts, there are several factors to consider during the injection molding process:

- Material selection: Choosing the right acrylic material is vital for achieving an aesthetically pleasing product. Some additives can enhance the clarity, color, and surface finish of the final part.

- Mold design: Proper mold design can ensure even filling and minimal defects in the finished part. The mold texture can also be tailored to achieve various surface finishes, from glossy to matte.

- Injection speed and parameters: Fast injection speeds and carefully selected molding parameters can help achieve a smooth, glossy surface finish. However, be careful not to sacrifice product quality for appearance, as excessive speeds can lead to other issues.

- Post-molding finishing: Some parts may require additional finishing processes after molding, such as polishing, painting, or coating, to achieve the desired final appearance.

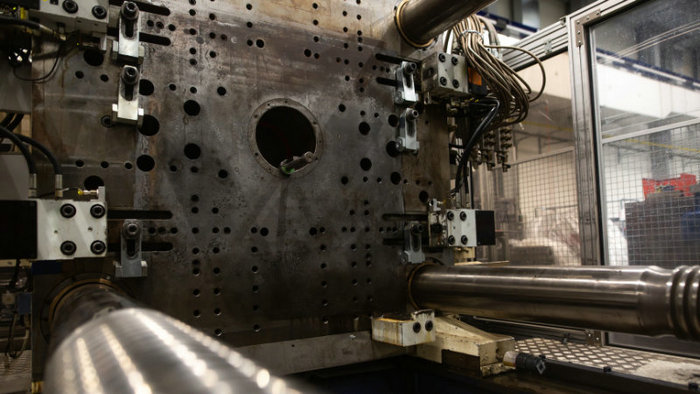

Temperature Management in Injection Molding

Acrylic melts at a temperature range of 130-140 degrees Celsius and can operate at a maximum temperature between 65 and 93 degrees Celsius. This makes acrylic suitable for operations under moderately high temperatures, and it can also be conveniently molded using heat. Its low thermal conductivity makes acrylic an exceptional insulator against heat.

When it comes to acrylic plastic injection molding, maintaining optimal temperature is essential for ensuring the quality and efficiency of the process. In this section, we will discuss the importance of temperature management and offer some tips on how to achieve it.

Firstly, drying temperature plays a critical role in preparing the plastic for processing. Acrylic, or PMMA, has a water absorption rate of 0.3-0.4%. To avoid bubbles, gas lines, and diminished clarity in the final product, it is crucial to keep the humidity level below 0.1%, typically around 0.04%. A well-maintained drying temperature can help accomplish this.

When it comes to melt temperature, it’s essential to consider the product’s quality and cycle time. Acrylic injection molding necessitates an appropriate melt temperature, which will have a significant impact on the resulting product. It’s worth noting that the melting point of acrylic is around 130-140 degrees Celsius. Within that range, you should find an optimal melt temperature that strikes a balance between quality and cycle time.

Now, let’s talk about mold temperature.

It’s essential to consider the injection mold temperature as it directly impacts the quality of the final product. A higher barrel temperature, for example, requires a lower moisture content in the acrylic sheets (0.02%), while a lower barrel temperature necessitates higher moisture removal (0.05%).

The temperature of the mold influences the dimensional stability and surface quality of the finished product. Thus, managing the mold temperature during the injection molding process is crucial. Here are three tips to help maintain ideal mold temperature:

- Use a temperature control system: To maintain the mold temperature, integrate a precise temperature control system.

- Monitor the mold temperature closely: Keep an eye on the actual mold temperature and make adjustments if needed.

- Optimize cooling channels: A good mold design includes efficient cooling channels, and they should be properly maintained to ensure effective heat removal.

Additional Considerations in Acrylic Molding

When dealing with acrylic injection molding, there are a few other factors you should keep in mind to ensure a smooth process and high-quality results. In this section, we’ll discuss heat deflection temperature, ultrasonic welding, and mold cost.

Heat Deflection Temperature: It’s essential to consider the heat deflection temperature (HDT) of acrylic during the molding process. HDT represents the temperature at which the material starts to deform under a specific load. For most acrylic materials, the HDT lies between 80-100°C. Maintaining temperatures below the HDT will ensure that your final product maintains its shape, has good optical properties, and has high dimensional accuracy.

Ultrasonic Welding: In cases where you need to join two or more acrylic parts, you might want to consider ultrasonic welding as a suitable technique. Ultrasonic welding uses high-frequency sound waves to generate heat, which then melts the plastic and fuses the parts together. It’s a quick and efficient method that leaves no visible marks and is especially useful for acrylic products requiring a clear and clean finish.

Mold Cost: Lastly, you should be aware of the costs associated with producing the mold for acrylic injection molding. High-quality molds can be costly due to factors such as complexity, size, and material. To minimize mold costs, consider the following:

- Simplifying your part design

- Reusing mold components when possible

- Selecting appropriate materials for the mold

Impact on Environment and Health During Acrylic Injection Molding

Certain aspects of the acrylic injection molding process can contribute to environmental concerns. As we look at the energy consumption of injection molding machines, they have improved and now use 20%-50% less energy compared to a decade ago. Yet electricity consumption remains a vital consideration, as it significantly impacts the environment.

During the acrylic injection molding process, various hazardous fumes and vapors may be produced, posing potential health risks if inhaled. To ensure the health of individuals involved in this process, proper ventilation and fume control solutions must be implemented within the manufacturing facility.

Alternatives and Comparisons

In this section, we’ll compare different molding materials, including polycarbonate, ABS, and other synthetic plastics, highlighting their properties and applications.

- Polycarbonate (PC): This transparent thermoplastic is known for its high impact resistance, making it an excellent alternative to acrylic for applications requiring greater durability. Polycarbonate is often used to create products like safety equipment, automotive components, and eyeglass lenses. Keep in mind that PC does typically have lower transparency than acrylic, but it can still be an ideal choice when impact resistance is a priority.

- Acrylonitrile Butadiene Styrene (ABS): As another synthetic plastic, ABS has gained popularity due to its low cost, ease of injection molding, and good mechanical properties. Although not as transparent as acrylic or polycarbonate, ABS is a solid option for projects that don’t require high levels of optical clarity. Some common uses for ABS include automotive parts, toys, and household appliances.

- Polypropylene (PP): This versatile thermoplastic has a good balance of chemical resistance, strength, and flexibility. While not transparent like acrylic, polypropylene is widely used in a variety of applications, such as packaging, automotive components, and consumer goods. If you’re looking for a material that offers excellent resistance to chemicals and fatigue, PP may be a suitable choice.

- Alternative Transparent Thermoplastics: There are several other transparent materials available for injection molding. Some examples include:

- ASA (Acrylonitrile Styrene Acrylate): Known for its excellent UV resistance and weatherability, ASA is often used for outdoor applications.

- COC (Cyclic Olefin Copolymer): Has a unique combination of transparency, chemical resistance, and low water absorption, making it suitable for medical devices and optical applications.

- PCT (Polycyclohexylenedimethylene Terephthalate): Offers superior heat resistance and optical clarity, making it ideal for demanding environments like automotive lighting.

Frequently Asked Questions

What are the advantages of acrylic injection molding?

Acrylic injection molding offers multiple benefits such as high optical clarity, excellent light transmission, and good color stability. With light transmission greater than 92%, acrylic has a clarity similar to glass. In addition, acrylic parts are known for their strength, durability, and resistance to weathering and UV radiation, making them suitable for a wide range of applications.

How do I choose the right mold material for acrylic?

Selecting the right mold material for acrylic injection molding depends on factors like your budget, required mold lifetime, and part complexity. Steel molds are often preferred for their durability and ability to provide high-quality finished parts. However, aluminum molds can be a cost-effective alternative for short-run production or less demanding applications. Collaboration with your mold manufacturer can help you choose the best mold material to meet your project needs.

What are common applications of acrylic injection molded products?

Acrylic injection molded products have numerous applications, including automotive parts (like taillights and dashboard components), lenses for cameras or eyeglasses, light diffusers, signage, electronic device housing, and decorative items. Acrylic’s excellent optical properties and durability make it a popular choice for these diverse applications.

What factors affect the quality of acrylic injection molded parts?

Several factors can impact the quality of your acrylic injection molded parts. The most critical factors include mold material and design, plastic material humidity (preferably below 0.1%), injection molding process parameters (such as temperature, pressure, and cooling time), and proper material handling. These factors contribute to reducing defects like bubbles, gas lines, and diminished optical clarity.

How does acrylic injection molding compare to other techniques?

Acrylic injection molding is a versatile and efficient process that can create complex parts with high precision and surface quality. The process is generally faster and more cost-effective compared to other techniques, such as machining or casting. Injection molding also allows for high-volume production, which may not be feasible with other fabrication methods. However, it is essential to consider that the initial investment in mold creation can be more substantial, especially for sophisticated designs.

How can I prevent defects in acrylic injection molded products?

To minimize defects in acrylic injection molded products, ensure that the molding process parameters are optimized and the material is handled appropriately. The most crucial step is to limit moisture absorption in the acrylic material (typically 0.3-0.4%) and maintain the required humidity level of less than 0.1%. Proper mold design and consistent process control can help avoid issues like bubbles, gas lines, and compromised clarity. Collaborate with your injection molding service provider to establish best practices for preventing defects in your acrylic parts.