What differentiates production injection molding and prototype injection molding is the purpose of the mold making. The former one is the prerequisite of high-volume production, while the latter one, also known as rapid injection molding, creates accurate, functional parts quickly so teams can refine the designs. Keep reading, and you will know why prototype injection molding is your best helper in decision-making before mass production.

Prototype vs. Production Injection Molding

While prototype and production injection molding share the same core process—injecting molten plastic into a mold—they are different in their purposes. To better illustrate this idea, here is a side-by-side comparison of the two production methods.

| Feature | Prototype Molding | Production Molding |

|---|---|---|

| Tool Material | Aluminum or soft steel | Hardened steel |

| Typical Volume | Under 500 parts | Thousands to millions |

| Lead Time | 1–4 weeks | Several weeks to months |

| Tool Life | Short-term (100s of cycles) | Long-term (100,000s+ cycles) |

| Primary Goal | Design validation, functional testing | Cost-efficient, high-volume manufacturing |

Generally, prototype molding uses less durable tooling for speed and flexibility, accepting higher per-part cost to de-risk the design. Production molding invests in durable, precision tooling to minimize per-part cost over a long product life. Moving from one to the other is the critical gate between successful development and full-scale manufacturing.

Benefits of Prototype Injection Molding Service

Design Validation and Functional Testing

Prototype injection molding allows engineers to produce parts that closely match the final product’s form, fit, and function. By using the same or similar materials intended for mass production, teams can test mechanical strength, tolerances, and performance under real-world conditions.

Functional testing becomes more reliable because injection-molded prototypes exhibit consistent surface finishes and dimensions. This supports early identification of design flaws such as wall-thickness imbalance, weak joints, or assembly issues.

The process also supports iterative design, allowing multiple rounds of improvements with minor mold adjustments. Designers can compare data from each version and confidently decide when the design is ready for production. This validation step reduces the risk of expensive rework once manufacturing scales up, which benefits the non-standard design of custom injection molding to a considerable extent.

Material and Process Accuracy

This method offers material flexibility and process precision that help mimic production conditions. Manufacturers can test different resins such as ABS, polypropylene, or nylon to evaluate performance variations and ensure that material behavior in prototype form reflects final production characteristics.

Prototype molds also allow process adjustments—such as pressure, temperature, and cycle times—similar to those in full-scale manufacturing. These controlled trials improve process predictability and reduce setup errors later. As a result, teams gain dependable data while keeping development efficient and accurate.

Plastic Materials Used in Prototype Injection Molding

Thermoplastics Selection

Thermoplastics are the most common materials in prototype injection molding because they can soften when heated and harden when cooled without chemical changes. This property allows easy reprocessing and supports quick production cycles.

Common thermoplastics include ABS, polypropylene, polycarbonate, nylon, and acetal. Each offers a distinct balance of strength, flexibility, and cost.

- ABS offers strength and smooth surfaces for prototypes but limited heat resistance.

- Polypropylene is tough, flexible, and cost-effective, ideal for living hinges and packaging.

- Polycarbonate provides impact resistance, clarity, and heat tolerance, suitable for transparent, durable, and sterilizable prototypes.

- Nylon provides excellent wear resistance and strength for functional components like gears and bearings.

- Acetal (POM) offers low friction, high stiffness, and dimensional stability, making it ideal for precision moving parts such as rollers and fasteners.

Thermoplastics also allow the production of plastic parts purely for testing of end-use properties. Engineers often choose grades that resemble the intended production material to verify structural integrity and performance.

Factors Influencing Material Choice

Selecting a material for prototype molding depends on mechanical needs, part designs, and expected use conditions. Engineers weigh strength, temperature limits, and dimensional stability against cost and tool life.

Functional testing often favors materials that mirror the final production resin, ensuring predictable performance. Aesthetic goals like transparency, color, or texture also guide selection.

Production factors, such as cycle time and mold wear, influence decisions too. Abrasive-filled materials like glass-reinforced nylon can shorten tool life and give rise to tooling costs, while softer plastics flow more easily.

Prototype Mold Creation and Design

CAD Model Development

Engineers begin prototype mold creation with a CAD model that defines the shape, features, and dimensions of the part. The model must capture functional details like wall thickness, draft angles, and undercuts to ensure proper mold filling and ejection, and also consider how features like undercuts will be handled in the prototype mold, often through simplified tooling like manual inserts or core pins to maintain flexibility and cost-efficiency.

In this stage, design teams often use parametric modeling software to make quick adjustments for different tests or materials. Changes to the CAD model can immediately show how design modifications affect part geometry and mold construction.

Key considerations include:

- Material shrinkage: Adjusting dimensions to account for thermal contraction after cooling.

- Gate placement: Identifying where molten plastic will enter the cavity.

- Mold separation lines: Ensuring clean parting to avoid flash or distortion.

Accurate CAD data allows for smooth mold manufacturing and reduces rework later in the prototyping process.

Part Designs and Tolerances

The accuracy of part geometry and tolerances determines whether prototype parts represent production-level quality. Tight tolerances allow for precise testing of assemblies, fit, and performance under real conditions.

During mold creation, designers balance manufacturable limits with functional demands. Overly strict tolerances can increase machining time and cost, while loose ones may yield poor results during prototype evaluation.

Engineers use coordinate measuring machines (CMM) or 3D scanners to verify dimensions. They also evaluate how gate locations, draft angles, and cooling channels affect warping or shrink rates.

By controlling geometry and dimensional accuracy, prototype molds produce reliable test parts that help confirm both design intent and manufacturability.

The Prototype Injection Molding Process

Step-by-Step Overview

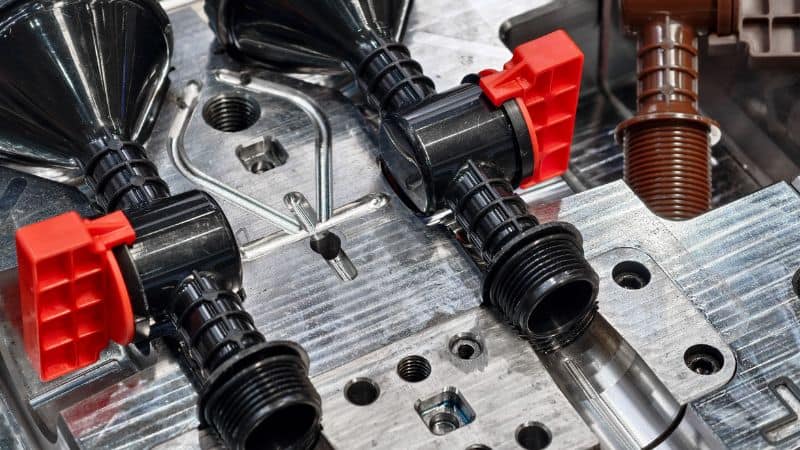

The injection molding process starts with designing a 3D model of the part using professional software. From this model, a prototype mold is CNC machined from aluminum or brass. These softer metals reduce cost and lead time while still producing accurate and durable molds for testing.

Once the mold is complete, it is placed in an injection molding press. The chosen thermoplastic resin is heated until molten, then injected into the mold cavity under pressure. The plastic cools and solidifies in the shape of the cavity. Each cycle typically lasts under a minute, producing multiple identical parts efficiently.

After cooling, the mold opens, and ejector pins release the formed part. Engineers then trim any excess material and inspect the prototype for accuracy and surface finish.

Compared to 3D Printing and CNC Machining

Prototype injection molding differs from 3D printing and CNC machining in material behavior, precision, and cost per part.

| Aspect | Injection Molding | 3D Printing | CNC Machining |

|---|---|---|---|

| Material Used | Production-grade thermoplastics | Layered polymers or resins | Solid blocks of material |

| Surface Finish | Smooth, consistent | Varies, often rough | Smooth but limited shapes |

| Accuracy | High | Moderate | High |

| Best For | Functional testing, medium volumes | Early design validation | Structural prototypes |

3D printing delivers fast, low-cost models for verifying form and fit but lacks the material strength and surface quality of molded parts. CNC machining creates durable prototypes but can be expensive for complex geometries or multiple units. Injection molding provides a balance—rapid, realistic parts that mirror final production characteristics.

Quality Checks and Iteration

Quality evaluation begins after the first molded samples are produced. Teams measure dimensional accuracy, check for defects like warping or sink marks, and test fit and function in assemblies. The consistency of prototype injection molding makes it ideal for verifying tolerances and material performance.

If testing reveals problems, engineers adjust mold design, processing temperatures, or injection pressure. Because aluminum molds are easy to machine, changes can be made in hours rather than weeks. This supports fast iteration and design verification.

Prototype injection molding services often include detailed inspection reports and part validation data. These checks ensure that when production tooling begins, the design is proven to work both technically and manufacturably, saving time and reducing the risk of costly redesigns later.

Applications and Industry Use Cases

Product Development and Rapid Prototyping

In product development, prototype injection molding is used to create functional prototypes that mimic final products in both form and material for pre-production validation.

The process supports short turnaround times and low production volume, which helps teams iterate designs quickly. This provides accurate feedback for refining geometry and performance.

Companies use this method to verify mold designs, evaluate part strength, and assess material behavior. This capability shortens lead times from concept to approved production design.

Medical Devices and Automotive Components

The medical industry uses prototype injection molding to produce precise and biocompatible components, such as syringe parts, surgical tools, and instrument housings. Since medical devices must meet stringent regulatory and biocompatibility standards, prototype molding provides essential functional parts for early verification of safety, usability, and compliance.

In automotive manufacturing, injection-molded prototypes play a role in testing structural and interior parts like clips, connectors, and dashboard elements. Prototypes allow engineers to verify mechanical strength, temperature resistance, and assembly alignment before large-scale tooling begins. This lowers the risk of redesign and tooling adjustments during production.

Consumer Electronics and Other Sectors

Consumer electronics rely on prototype injection molding to achieve precise shapes, surface textures, and tight tolerances for housings, cases, and connectors. Working prototypes help verify assembly compatibility with internal hardware and create consistent aesthetic quality for end users.

Small production of injection-molded parts helps product teams test ergonomics, color, aesthetics, and texture efficiently. This makes testing under thermal, mechanical, or environmental stress conditions possible without major cost.

The process is equally critical in aerospace and industrial equipment for validating complex, high-specification parts before committing to full-scale production tooling.