Metal stamping is a manufacturing process that shapes the metal parts that power everyday products, from cars and appliances to electronics and medical devices. In this introductory guide, we will reveal how this process continues to support innovation across industries and why it remains essential to producing reliable metal parts at scale.

Fundamentals of Metal Stamping

Metal stamping is a manufacturing process that forms metal sheets or coils into defined shapes using a press and custom dies. The process may include several operations, such as:

- Blanking – cutting the basic shape from a sheet

- Punching – creating holes or cutouts

- Bending – forming angles or curves

- Embossing – raising or recessing surface features

These actions occur under high pressure, often in a cold state, to maintain material strength and precision. This metal stamping technique is referred to as “cold-forming,”which is the most common technique. However, “hot stamping” is also used for specialized applications.

Modern stamping uses computer-controlled presses and precision dies to meet high-performance standards. Automation and digital design now allow faster setup, improved accuracy, and lower production costs.

Key Metal Stamping Processes

Blanking and Piercing

Blanking and piercing are often the first steps in metal stamping. Blanking cuts flat pieces, called blanks, from a larger sheet. These blanks become the base for later forming operations. The process uses a die and punch to shear the metal cleanly, producing parts with accurate edges and minimal waste.

Piercing creates holes or openings in the blank using similar tooling. It removes unwanted material rather than forming a new shape. Manufacturers often perform blanking and piercing in the same press stroke to improve efficiency.

Tool alignment, die clearance, and material thickness determine edge quality and dimensional accuracy. These processes use high-strength tool steel and proper lubrication to reduce wear and burr formation, which is essential for producing consistent parts in automotive, appliance, and electronics manufacturing.

Bending and Flanging

Bending changes the shape of metal sheets without altering their thickness. It uses a punch and die to apply force along a straight line, forming angles or curves. The process depends on material ductility, bend radius, and press tonnage.

Flanging extends the edge of a part by bending it at a specific angle, often 90 degrees or less. This strengthens edges, improves fit, and allows parts to connect with other components.

Both bending and flanging require careful control of springback, the metal’s tendency to return slightly toward its original shape. Operators adjust tooling geometry or use overbending to maintain accuracy.

Punching and Coining

Punching removes material from a sheet to create holes, slots, or shapes. It uses a punch and die similar to piercing but often at higher speeds for repetitive patterns. This process supports high-volume production with tight tolerances.

Coining compresses metal under extreme pressure to form fine details or adjust thickness. It refines surface finish and enhances dimensional precision by forcing the material to flow into the die cavity.

Coining is widely used for producing embossed logos, contact points, and precision washers. It also eliminates burrs and sharp edges, reducing secondary finishing. Together, punching and coining provide the accuracy needed for electrical connectors, fasteners, and decorative components.

Embossing and Deep Drawing

Embossing raises or recesses specific areas of sheet metal to create textures, patterns, or identification marks. It uses matched male and female dies that press the material into the desired relief without cutting it. The process enhances appearance and can increase stiffness in thin sheets.

Deep drawing forms flat blanks into hollow or cup-shaped parts. It stretches the metal into a die cavity using a punch while controlling material flow with a blank holder. This process is ideal for producing fuel tanks, cans, and kitchen sinks, which are often made with materials with good ductility, like aluminum and stainless steel.

Materials for Metal Stamping Operations

Common Types of Metals Used

Manufacturers often use steel, stainless steel, aluminum, copper, and brass for metal stamping. Each has specific benefits depending on the application.

- Carbon steel is strong, affordable, and easy to form, making it useful for automotive and industrial parts.

- High-strength low-alloy (HSLA) steel provides strength without adding much weight.

- Stainless steel offers corrosion resistance and durability for food, medical, and marine components.

- Aluminum is lightweight and resists corrosion, making it ideal for transportation and aerospace.

- Copper and brass provide excellent electrical conductivity for electronic and HVAC parts.

Other metals such as titanium, nickel alloys, and zinc alloys appear in specialized uses where heat resistance, strength, or complex shapes are required.

Material Properties and Suitability

The best material depends on the mechanical properties needed for the part. Strength, ductility, and hardness affect how a metal sheet forms under pressure.

Formability determines how easily the metal bends or stretches without cracking. Softer metals like aluminum and low-carbon steel form well, while harder alloys may need more force or specialized tooling. However, it should be noted that within each metal type, specific grades and tempers offer varying levels of formability.

Corrosion resistance matters when parts face moisture or chemicals. Stainless steel and coated steels protect against rust, while aluminum naturally resists oxidation.

Conductivity is important for electrical components, making copper and brass preferred choices. Weight also influences selection; lighter metals reduce total product mass and energy use.

Balancing these factors helps ensure that stamped metal components meet both performance and cost goals.

Sheet Metal Stamping Equipment and Production

Metal Stamping Dies and Tooling Types

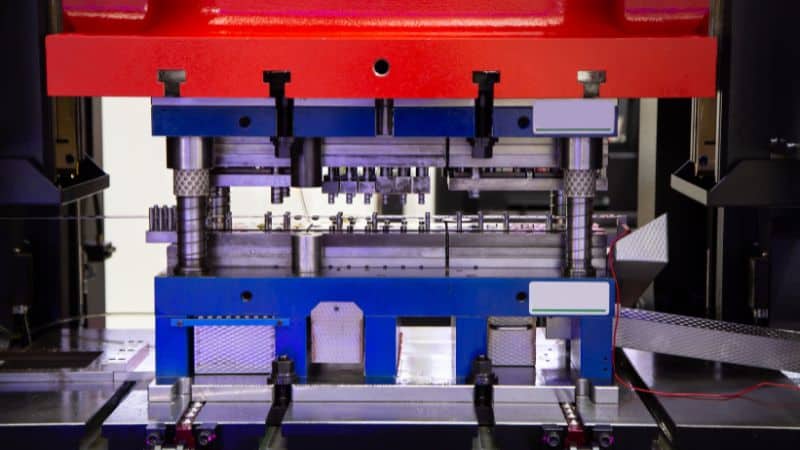

A stamping die is a specialized tool used in a press to cut or form metal sheets into specific shapes. It consists of two main parts: the die set (bottom section) and the punch (top section). Together, they control the shape and dimensions of the final part.

Common types of stamping dies include:

| Die Type | Function |

|---|---|

| Blanking Die | Cuts flat shapes from sheet metal. |

| Piercing Die | Creates holes or openings. |

| Forming Die | Bends or shapes the metal without cutting. |

| Compound Die | Performs multiple operations in one stroke. |

| Progressive Die | Moves the sheet through several stations for multiple operations. |

Each die type supports different production needs. Progressive dies are often used for high-volume runs, while single-station dies suit simpler or lower-volume parts.

Types of Stamping Presses

Stamping presses provide the force needed to shape metal sheets using dies. They come in two main types: mechanical presses and hydraulic presses. Mechanical presses deliver consistent, rapid strokes, making them ideal for high-volume production. Hydraulic presses use fluid pressure for greater control and are preferred for thicker or more complex parts.

High-speed presses operate at much higher stroke rates—often hundreds of strokes per minute. They use advanced feed systems that move metal coils through the die quickly and precisely. These presses are common in automotive and electronics manufacturing, where small, detailed components must be produced in large quantities.

Multi-Slide and Progressive Stamping

Multi-slide stamping uses several moving slides that strike the metal from different angles. This setup allows for complex bends and forms in a single operation. It reduces the need for secondary machining and can handle intricate geometries efficiently.

Progressive die stamping feeds a metal strip through a series of dies, with each station performing a specific action such as punching, bending, or cutting. The final station produces a finished part. This method is efficient for continuous production and maintains tight tolerances across thousands of identical parts. In contrast, transfer die stamping uses a separate mechanical system to move individual parts from one station to the next.

Both methods improve material utilization and reduce handling time. They are widely used for connectors, brackets, and small mechanical parts where precision and repeatability are essential.

Precision Stamping Techniques

Precision stamping focuses on achieving extremely tight tolerances and smooth finishes. It often uses fine blanking, micro-stamping, or servo-driven presses to enhance control over pressure and movement. These techniques allow for clean edges and accurate dimensions without additional finishing steps.

Manufacturers use CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) to maintain consistency. Engineers use CAD software to model dies, simulate material deformation, and verify tolerances before production. CAM software then converts these digital designs into machine instructions for tool fabrication. This integration reduces design errors and speeds up tool production.

3D modeling allows engineers to visualize die sets and optimize layouts for efficient metal flow. Combined with computer simulations, they help predict wear points, improve accuracy, and shorten lead times in die manufacturing.

Quality Control and Post-Processing

Inspection and Quality Assurance

Quality control in metal processing begins with inspection and testing at multiple production stages. Technicians use tools such as calipers, micrometers, and coordinate measuring machines (CMM) to verify part dimensions and tolerances.

In-process quality control (IPQC) checks help detect deviations early, preventing large batches of defective parts. Statistical Process Control (SPC) charts are often used to track production data and maintain process stability.

A typical inspection plan may include:

| Stage | Purpose | Method |

|---|---|---|

| Material check | Verify metal grade and thickness | Visual and chemical tests |

| In-process | Detect forming or alignment errors | SPC, sampling |

| Final inspection | Confirm specifications | Dimensional and surface checks |

Consistent documentation of results supports traceability and compliance with industry standards such as ISO 9001.

Finishing and Post-Processing Steps

After stamping and inspection, parts often require post-processing to improve surface quality and performance. Common finishing steps include deburring, polishing, electroplating, and coating. These processes remove sharp edges, enhance corrosion resistance, and prepare components for assembly or painting.

Heat treatment may also be applied to strengthen the metal or relieve internal stresses from stamping. Cleaning processes like ultrasonic washing remove oils and particles left from production.

Manufacturers choose finishing methods based on the part’s function and material type. For example, stainless steel parts may receive passivation, while aluminum components might be anodized for added protection and appearance.

Applications of Metal Stamping

Choosing Moldie for Metal Stamping Services

Selecting a reliable metal stamping service involves evaluating technical capability, quality control, and customization options. A qualified provider uses advanced design and manufacturing technologies to ensure consistent results. Buyers should review and contact the company about certifications, production capacity, and tolerance limits before placing orders.

Well-established production processes and experience, along with strong customer support and clear communication, help align design goals with manufacturing outcomes. Some suppliers also offer prototype development and high-volume production, allowing clients to test and scale efficiently.

Here at Moldie, we have exactly what you need: proven experience across various metal manufacturing practices and industries. Contact us today for your dependable parts and better long-term value!

Frequently Asked Questions

What are the key design considerations for creating a part for metal stamping?

When designing a part for stamping, focuses should be placed on factors like material selection, bend radii (to avoid cracking), hole and notch sizes (relative to material thickness), and the inclusion of features like ribs or beads to strengthen the part.

How do I choose between a progressive die and a transfer press?

The choice often depends on the part’s size and complexity. Progressive dies are ideal for smaller, flatter parts that can be carried on a metal strip through multiple stations. Transfer presses are better suited for larger parts or those that require significant 3D forming, as a mechanical system transfers the part from one station to the next, freeing it from the carrier strip.