Silicon molding is a manufacturing process that uses liquid silicone rubber to create molds. The silicone rubber is poured into a master mold or pattern and then cured to form a silicone mold.

Silicone molds allow for high production volumes and a long lifespan compared to other mold materials like plaster or wood. They are often used for casting jewelry, prototypes, dental molds, special effects pieces, and more.

This article will provide an overall introduction to the silicon molding process for you.

Why Choose Silicone

First, silicone has remarkable resistance properties. It can withstand extreme temperatures, both hot and cold, and maintain its shape and function. This makes it ideal for applications that require materials to perform under harsh conditions.

In terms of stability, silicone remains virtually unchanged when exposed to various environmental factors such as UV rays, moisture, and ozone. In your projects, you can expect this property to contribute to the longevity of the final product.

You’ll notice that silicone is incredibly flexible, allowing it to be molded into intricate and complex shapes. Its tensile strength and elasticity make it a perfect material for use in various industries. Parts made from silicone can stretch and bend without breaking, making them suitable for a wide range of applications.

Durability is another key aspect of silicone. It resists wear and tear, ensuring your final product maintains its quality over time. Silicone’s ability to resist compression set and maintain its performance even with continuous use makes it a reliable material choice.

As for transparency, silicone allows light to pass through its clear form, making it an excellent option when visual elements are crucial or if the product must be inspected for impurities or defects.

Finally, silicone is a biocompatible material, which means it’s non-toxic and doesn’t cause any adverse reactions when it comes into contact with the human body. This property makes it a popular choice for medical applications.

What is the Silicon Molding Process

One widely used method is liquid injection molding (LIM). LIM involves injecting liquid silicone rubber (LSR) into a mold, where it quickly hardens and takes the desired form. This method is known for its precision and efficiency, making it suitable for producing intricate parts in large volumes.

Another common technique is injection molding. Similar to liquid injection molding, this process involves melting silicone and injecting it into a mold. The mold’s temperature and pressure are carefully controlled, ensuring the silicone solidifies uniformly and maintains the desired shape. Once the part is cooled, it is removed using an ejector pin.

Compression molding is an older, yet still relevant, method for molding silicones. It involves placing a pre-measured amount of silicone into the mold, which is then compressed under high temperature and pressure. Although this process is slower than injection molding, it is cost-effective for lower-volume production runs.

Transfer molding is another technique used to manufacture silicone parts. In this process, the material is preheated in a separate chamber before being transferred into the mold cavity, where it hardens and takes shape. Transfer molding is a suitable option for moderately complex designs and smaller production volumes.

Reaction injection molding (RIM) is a method that combines elements of injection molding and chemical reactions. In this process, two or more reactive components are mixed, injected into the mold, and allowed to cure. RIM is particularly well-suited for large, lightweight parts with complex geometries.

Finally, overmolding refers to the process of molding one material over another. In the case of silicones, this process allows you to create multi-material parts with different properties (e.g., soft and hard areas), enhancing the overall functionality and aesthetics of the final product.

Typical Silicon Materials and Components

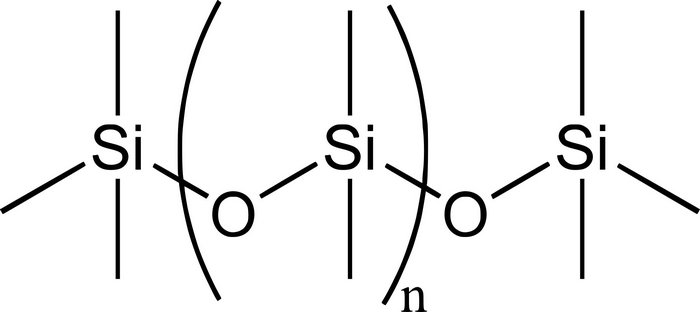

When it comes to silicone molding, the material you choose plays a vital role in the final product. Silicone is a versatile and durable material that comes in a variety of forms, including liquid silicone and liquid silicone rubber (LSR). This section will explore the different components and types of silicone materials used in molding processes.

Liquid Silicone Rubber (LSR) is a popular choice for molding projects because it combines the benefits of both thermoset and thermoplastic materials. It is an elastomer that offers a wide range of hardness, excellent durability, and resistance to environmental and mechanical stress. When preparing LSR, you’ll need to mix two components – Parts A and B -Both are liquid, but only one part contains the catalyst – in a 1:1 ratio to create the final mixture. The viscosity of this material makes it ideal for easily filling complex mold cavities.

Besides LSR, you can also work with High Consistency Rubber (HCR), a more solid silicone material that typically comes in sheets or rolls that need to be vulcanized or heated to create the final product. HCR requires a different molding approach, such as compression molding or transfer molding. While not as versatile as LSR, HCR also offers excellent durability and resistance to various conditions.

To customize your silicone material, you can add various additives to alter its properties:

- Fillers – Enhance the silicone’s mechanical properties, such as tensile strength and tear strength.

- Pigments – Give your silicone a specific color to match your design requirements.

- Specialty additives – Improve flame resistance, UV stability, or even make the silicone conductive.

When selecting a silicone for molding, it’s important to consider the material’s hardness, which is measured in durometer. The durometer of the silicone can influence how it interacts with your mold and affects the final product. Typically, silicone materials have a range of hardness levels, with lower numbers indicating a softer, more flexible material. Some common durometer values for silicone molding include:

- Soft: 10A to 30A

- Medium: 31A to 50A

- Hard: 51A to 70A

Equipment in Silicon Molding Process

In this section, we’ll walk you through some of the crucial equipment you’ll encounter in the silicon injection molding process, making your work more effective and efficient.

First and foremost, you’ll need an injection molding machine. This machine is the core component of the process, responsible for injecting the liquid silicone material into the mold cavity. The machine comprises a nozzle that directs the material flow and a plunger that pushes the silicone into the mold.

In addition to the injection molding machine, a static mixer is another essential piece of equipment. The mixer ensures that the liquid silicone material is combined accurately and homogeneously before being injected into the mold. By maintaining proper consistency and uniformity, you can ensure high-quality, repeatable results in your finished products.

Here’s a list of essential equipment for the silicone molding process:

- Injection molding machine

- Nozzle

- Plunger

- Static mixer

- Mold release

- Mold cavity

- Mixers

- Container

Before starting the process, it’s a good practice to apply a mold release agent to the mold cavity. Mold release agents help to prevent the silicone material from sticking to the mold surface and facilitate a smoother release of the finished part. This step is crucial in preserving the integrity of your mold and ensuring the best possible surface finish on your parts.

To ensure optimal results, it’s essential to select the appropriate container to store the liquid silicone material. Containers should be designed to hold the specific product and withstand the heat and pressure generated during the process without warping or releasing any contaminants.

Silicon Molding Process Specifics

Firstly, it is crucial to heat the silicone at the right temperature for the curing process, typically between -65° and 400° Celsius. Proper curing helps you achieve the desired properties like shape, hardness, elasticity, and color in the final product. Remember, an appropriate curing temperature is essential for a successful molding process.

The pressure applied during the molding process is dependent on the type of silicone being used and the end product’s requirements. Maintaining the right pressure ensures that the silicone correctly fills the mold cavities and prevents any voids or air bubbles.

The cooling phase is equally important, as it allows your final product to solidify and take its final shape. The cooling time primarily depends on the part’s size, shape, and specific requirements.

Another thing to consider is the accuracy of your final product. Silicone molding can produce parts with high precision and excellent surface finish. To ensure this, you need to use proper molds and dedicated equipment like mixers and injectors.

Here is a list of some crucial components in the silicone molding process:

- Mixers: To ensure an even mixture of materials before they are injected into the mold.

- Injector: It plays a pivotal role in injecting the silicone material at the right pressure and temperature into the mold.

- Overmolding: A technique used for encapsulating electrical components or adding a soft-touch layer to a part.

- Stripping/Flashing: To remove excess silicone material from the final part.

- Ejection: Carefully remove the final part from the mold, ensuring that the part is undamaged.

Nowadays, 3D printing technology has already introduced additive manufacturing processes in the field of silicone molding, further expanding its capabilities.

The Role of Temperature

Temperature plays a crucial role in the final quality and properties of your finished product.

Firstly, managing the melt temperature is essential to achieve the desired results. All plastic injection molding companies must closely monitor and control the melt temperature throughout the process. Even if your injection molding machines come with pre-set melt temperatures, you should keep a watchful eye on the entire process. This helps ensure that your silicone mold maintains its quality and durability.

Now, let’s talk about mold temperature. This is another area where temperature has a significant impact on the final product. Ideally, the molding process should be performed at an optimal low temperature to allow the silicone to retain its properties, such as temperature resistance and flexibility. This balance of temperature enables the production of pliable, durable parts and also minimizes part weight variations.

In addition, liquid silicone rubber (LSR) is known for its ability to maintain its original shape even when subjected to extreme high and low temperatures. This high compression set sets LSR apart from other elastomeric polymers, making it a popular choice for applications that require resistance to a wide range of temperatures.

Safety and Contact

Wearing proper safety equipment such as gloves, protective eyewear, and a mask can help protect you from any potential hazards. Here are some key points to keep in mind about safety and contact when working with silicone molding:

- Gloves: Wearing gloves can help prevent direct skin contact with uncured silicone, which can occasionally cause irritation. Choose gloves made of materials like nitrile or latex, as these can offer chemical resistance and protection.

- Eye Protection: Protective goggles or safety glasses can help prevent any accidental splashes of uncured silicone from entering your eyes during the molding process.

- Ventilation: Ensure that you have adequate ventilation while working with silicone, as some formulations may release fumes during the curing process. A well-ventilated area can reduce the concentration of these fumes, making it safer for you to work.

Benefits of Silicon Molding

Firstly, silicone molding is known for its versatility. You can use it to create complex, detailed shapes, even with intricate geometries. This flexibility allows you to work on a wide range of projects, from prototyping to mass production.

Another great advantage of silicone molding is that it produces durable parts and components. The material can withstand temperatures ranging from -90°C to 250°C, as well as offer excellent heat and flame resistance. This makes it a perfect choice when you need items that can endure harsh environments.

One key aspect of this process is its ability to offer high precision. Silicone molding, specifically liquid injection molding, uses low viscosity material that accurately fills the mold, capturing the smallest details. This results in high-quality, dimensionally accurate parts that meet your specifications.

In terms of prototyping, silicone molding is a great choice. The process allows for rapid production, making it possible to create several prototypes in a short amount of time. Prototyping with silicone molding is also more cost-effective compared to other methods.

When it comes to minimizing material waste, silicone molding stands out. This process requires less material, as the mold cavity is filled accurately, without excess waste. This helps you save on materials and reduce overall costs.

Lastly, silicone molding can be easily automated. This leads to faster production times, higher efficiency, and less human error. An automated process lets you focus on other important aspects of your project, such as design or finishing touches.

Silicone Molding in Different Industries: The Products and Applications

Silicone molding is a versatile process utilized in various industries due to its durability, flexibility, and ability to produce high-precision components. In this section, we will explore how silicone molding serves different sectors, touching on its applications in medical, aerospace, automotive, construction, food, electronics, healthcare, energy, and manufacturing tech.

Medical and Healthcare: In these industries, the silicone molding process’s biocompatibility and sterilizability come in handy for creating medical devices and equipment. You’ll find silicone molded parts in prosthetics, implants, and tools like catheters and respiratory masks. Its customizable properties allow manufacturers to adjust the hardness and elasticity for patient comfort.

Aerospace and Automotive: Silicone rubber components manufactured through molding are critical in these sectors due to their resistance to extreme temperatures and environmental conditions. In aerospace, they’re used for making gaskets, seals, and connectors. In the automotive industry, silicone parts are used in engine components, electrical systems, and lighting.

Construction and Energy: Silicone molding has earned its place in construction and energy sectors due to its weather resistance and insulating properties. You’ll see silicone seals, gaskets, and insulation materials used in buildings, solar panels, and wind turbines. These components ensure structural stability and longevity under varying weather conditions.

Food and Electronics: The food industry benefits from silicone molding’s ability to create food-safe and easy-to-clean items, such as baking sheets, molds, and utensils. In the electronics sector, silicone rubber insulates and protects sensitive components from moisture, dust, and fluctuations in temperature. Common uses include enclosures, keypads, and connectors.

Manufacturing Tech: Silicone molding contributes significantly to other manufacturing technologies with its adaptability, ability to create intricate designs, and fast production times. This versatility enables manufacturers across various sectors to produce a wide range of products efficiently.

Frequently Asked Questions

What are the different types of silicone molding processes?

There are several types of silicone molding processes, including injection molding, compression molding, transfer molding, and liquid silicone rubber (LSR) molding. Each technique varies in terms of the mold-making process, materials, and applications. It’s important to choose the process that best suits your project’s requirements.

How does liquid silicone rubber molding work?

Liquid silicone rubber (LSR) molding involves injecting a two-part liquid compound into a mold. The compound is heated and cured within the mold, transforming into a solid rubber-like material. LSR molding is particularly useful when creating flexible, durable, and heat-resistant parts. It’s widely employed in the production of medical devices, automotive components, and consumer goods.

What is the difference between injection and compression molding?

Injection molding involves injecting the silicone material into a closed mold under high pressure, whereas compression molding relies on applying pressure and heat to the silicone material placed within an open mold. Once the mold is filled, it’s closed, and the material is cured. Generally, injection molding produces more complex parts and has faster production times, while compression molding is simpler and more cost-effective for small-scale projects.

How does a silicone injection molding machine function?

A silicone injection molding machine functions by melting the silicone material, and then injecting it into a mold through a nozzle and a runner system. It uses high pressure to force the material into the mold cavity, ensuring the silicone takes on the desired shape. Once the material is cured and cooled, the mold is opened, and the finished part is ejected.

What factors determine the price of a silicone injection molding machine?

The price of a silicone injection molding machine depends on various factors, such as the tonnage (clamping force), the size of the machine, the specific features the machine offers, and the general build quality. Additionally, the brand and after-sales services provided by the manufacturer play a role in determining the price.

Where can I find silicone molding services near me?

To find silicone molding services near you, try conducting a local search online. Websites like Google Maps and Yelp can help you find businesses offering these specialized services. Alternatively, you can also check out relevant industry forums and ask for recommendations. By researching and comparing different services, you will be better equipped to choose the best provider for your project.