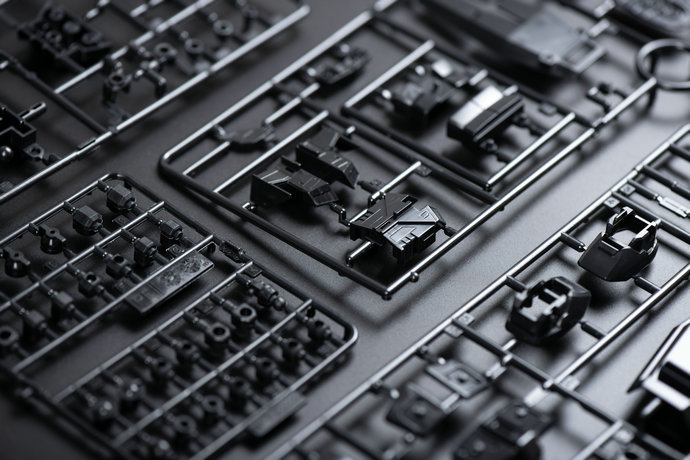

Injection molding is a manufacturing process that creates plastic parts by injecting molten material into a mold. One essential component of this process is the plastic sprue, which is crucial for the successful creation of plastic parts. The sprue, often made from polystyrene or polyvinyl chloride, serves as a passage through which the liquid material enters the mold, navigating its way to the part cavities where it solidifies.

Understanding the function of the plastic sprue is essential for the efficient design and production of molded parts. The sprue is typically connected to a network of runners and gates that direct and manage the flow of molten material into the mold cavities. Placing the sprue at the thickest section of the part can provide optimal cavity filling, reducing the risk of defects like voids, sink marks, and warpages.

Key Takeaways

- Plastic sprue is essential for directing molten material into the mold in the injection molding process.

- The sprue connects to runners and gates to manage the material flow and optimize part quality.

- Positioning the sprue at the thickest part of the molded product minimizes defects and improves efficiency.

Understanding Sprue and Its Role

In injection molding, the sprue is crucial in directing molten plastic into the mold chamber. It is a passage that connects the nozzle of the injection machine to the mold cavity. The sprue ensures that the molten plastic flows efficiently and effectively, minimizing defects and producing a consistent final product.

The sprue works with other components, such as the runner and gates. The runner is a distribution system that directs the molten plastic from the sprue to each cavity within the mold. This ensures that a consistent and controlled flow of plastic reaches every part, facilitating proper filling and formation.

When determining the diameter of the sprue, it is essential to consider the size and thickness of the molded part. The diameter should be large enough to accommodate the flow of molten plastic but not so large as to create excessive pressure and cause defects. It is typically designed to be tapered, gradually becoming narrower towards the end to help reduce the amount of material used and provide a smoother flow.

The sprue bush is another critical component when using a sprue. It is designed to secure the sprue and maintains proper alignment with the mold. It is typically fastened with two bolts to prevent disassociation caused by high injection pressures. Also, the sprue bush helps in ensuring accurate and consistent injection of molten plastic into the mold.

Injection Molding Process and Sprue

During injection molding to create plastic parts, the molten plastic flows through a sprue, a channel or passage connecting the injection unit to the mold cavity. It serves as the primary entry point for the molten material to flow into the cavities within the mold.

During the process, the injection unit heats the plastic material until it reaches a molten state. It then forces this material through the sprue, guiding the flow into the mold cavities. As the material cools and solidifies, it takes on the shape of the part specified by your mold design.

By optimizing the sprue design and location, you can reduce cycle time, minimize material waste, and prevent part defects such as warping or sink marks that may occur when the material doesn’t fill the cavities uniformly.

When designing the sprue and mold cavity, keep in mind the following considerations:

- Sprue location: Position the sprue at the thickest section of the part to effectively fill the cavity and prevent voids or defects.

- Sprue diameter: Ensure that the sprue is large enough to allow for adequate flow but not so large that it causes excessive pressure drops or shrinkage issues.

- Sprue length: Adjust the length of the sprue to balance the injection pressure and minimize the risk of material freeze-off or short shots.

By addressing these factors, you can successfully incorporate the sprue into your injection molding process and achieve high-quality plastic parts. Remember, the sprue’s primary function is to facilitate the smooth and efficient flow of molten plastic from the injection unit into your mold cavity. So, pay close attention to the design and dimensions of the sprue to ensure success in your injection molding endeavors.

Design and Formation of Plastic Sprue

In this section, you will learn about the design and formation of plastic sprue in injection molding.

First, it is essential to ensure the sprue’s proper design to optimize the molten plastic material flow. The sprue needs a draft, or a slight angle, to facilitate its release from the mold after the solidification.

The wider the draft, the easier it is to remove the sprue from the mold. The draft also helps reduce resistance during the filling phase, resulting in a smoother flow of molten plastic.

Upon entering the mold, the molten plastic flows from the sprue to the individual cavities via the runner system. This distribution system requires careful design, as it affects the quality and consistency of the final molded parts.

Different types of gates can be used to achieve the desired material distribution, such as edge gates, fan gates, or tunnel gates. Each gate type varies in size and shape, so choosing the appropriate gate for your specific application is crucial.

Edge gates, for example, are thin and narrow, ensuring a clean and seamless separation between the molded part and the sprue. On the other hand, fan gates have a wider opening, allowing for a more even flow of molten plastic material.

This results in a more uniform filling of the mold cavities, reducing the chances of material shrinkage or warping. Tunnel gates are typically used when molding more complex or delicate parts, as they allow for precise control over the flow of molten plastic material.

The solidification of the plastic material within the sprue should also be considered during the design process. Proper cooling channels should be incorporated into the mold, ensuring the material cools appropriately. This helps to prevent defects and improve the overall quality of the final part.

Sprue Runner Systems

In injection molding, the sprue runner system is crucial in distributing the molten plastic material throughout the mold, ultimately reaching each cavity.

As the molten plastic enters the mold through the sprue, it flows into the runners. Runners are channels that transport the material to the gates. These gates act as openings that allow the plastic to enter each cavity in a controlled manner. The gates and runners contribute to a smooth and balanced flow for consistent product quality.

There are different types of gates and runners in a sprue runner system. For instance, a sub-runner can branch off the leading runner, providing more precise control over the material distribution in multi-cavity molds.

Using sub-runners facilitates fine-tuning the filling process, reducing cycle time and improving the overall molding efficiency.

When designing a sprue runner system, it is essential to consider a balanced flow. This means that the molten material should reach each mold cavity simultaneously, with equal pressure and volume, resulting in consistent filling and uniform cooling of all parts within the mold.

Here are some key factors to consider in sprue runner systems:

- Runner dimensions: The diameter, length, and shape of runners should be carefully designed to maintain balanced flow and minimize pressure drops.

- Gate type and size: Choose the appropriate gate for your application, considering factors like part design, material, and desired flow characteristics. Ensure gate size is suitable to maintain consistent material flow.

- Balanced flow: Optimize the sprue and runner design to achieve balanced flow across all cavities, ensuring uniform filling and cooling.

Remember, an efficient sprue runner system is vital for successful injection molding. By considering each of these factors carefully, you can design a system that offers the desired balance of material flow and improves the efficiency and quality of your molded parts.

Challenges and Solutions in Sprue Design

Designing the sprues properly is essential for achieving quality products and an efficient process. This section will discuss some common challenges in sprue design and potential solutions.

One of the main challenges you may encounter in sprue design is pressure drop. As the plastic flows through the sprue, its velocity must be managed to minimize the pressure loss and ensure optimal flow rate.

A solution to this challenge is selecting the right sprue size and shape that allows for optimal flow and reduces resistance.

Another problem that may arise is insufficient volume in the sprue, leading to poor ejection and the formation of voids in the finished parts. Addressing this issue requires carefully calculating the required material volume and adjusting the sprue design to accommodate it. Additionally, using a proper ejection system will prevent part deformation and ensure uniform cooling throughout the part.

Regulating material flow in the sprue can also help avoid sink marks and warpages in the injected parts.

You may need to adjust the flow rate by optimizing the sprue’s diameter, runner size, and gate location to achieve this.

Regarding material waste and sustainability, sprue design plays a significant role. Optimizing the design can reduce the amount of material that needs to be reground, which saves resources and improves efficiency. Implementing a cold runner system for easily regrindable materials can also reduce waste.

By addressing these issues with proper design adjustments and optimization, you can ensure the production of high-quality plastic parts and improve the overall efficiency of your injection molding process.

Frequently Asked Questions

1. What are the types of runners in injection molding?

There are two main types of runners in injection molding: cold and hot runners. Cold runners are simple channels within the mold that direct molten plastic from the sprue to the mold cavity. They can be made from the same material as the mold and, therefore, cool down as the plastic solidifies, making removing the part from the mold easier.

On the other hand, hot runners are more complex systems designed to keep the molten plastic at the desired temperature as it travels from the sprue to the mold cavity. They typically include heaters or heating elements that maintain a consistent temperature, reducing material waste and improving the overall efficiency of the process.

2. How does sprue differ from runner in the molding process?

While both sprue and runner are channels that transport molten plastic in the injection molding process, they serve different functions. The sprue is the initial vertical passage connecting the injection molding machine nozzle to the mold cavity.

In contrast, the runner is a channel that distributes the plastic to multiple cavities or different parts of the mold. The sprue serves as the entry point for the molten plastic, while the runner’s primary role is to distribute the material evenly throughout the mold.

3. What role does Sprue play in casting?

In casting, the sprue plays a similar role to its function in injection molding. It is the vertical passage through which liquid material, such as molten metal or plastic, is introduced into the mold. The sprue creates a flow path for the material to enter the mold cavity, ensuring that the mold fills evenly and that the final part is free of defects and air bubbles. This eliminates excess material and waste.

In many casting processes, the sprue also helps control the flow of molten material through the injection machine nozzle, making it a critical component in creating high-quality cast parts.

4. What is the significance of the sprue shape?

The shape of the sprue significantly impacts the efficiency and quality of the injection molding process. A well-designed sprue should minimize material waste, facilitate the smooth flow of molten plastic, and reduce the risk of defects, such as voids, sink marks, and warpage in the final part. Typically, placing the sprue at the thickest section of the part would be best, enabling efficient filling of the cavity. A tapered or conical shape can help minimize pressure drops as the material flows through the sprue, ensuring a smoother and more controlled injection process.

5. How does a mold sprue bushing function?

A mold sprue bushing is a critical component in the injection molding process, connecting the nozzle of the injection machine to the mold’s runner system. It forms the interface between the injection machine’s nozzle and the sprue, enabling a tight seal and preventing leaks or material loss.

The sprue bushing ensures that the molten plastic material is efficiently and accurately transferred from the injection machine’s hose into the mold’s sprue, reducing waste and ensuring that the material reaches the mold cavity in the desired condition for optimal part production.

Order Plastic Parts in Bulk

You have no worries about plastic sprue quality when dealing with us. You can order high-quality plastic injection molding parts from us. Regardless of your location, we deliver fast, according to our agreement.

Please send us a message via the customer contact form on the site to order today.