These cast Aluminum molds are built on a robust LKM C50 + P20 base, which may range from AB to cast iron, ensuring resilience and longevity in every operation.

The inserts, including Dievar, H13, 8407, and 1.2344, can be tailored to fit your required material. Plus, adhering to global standards such as HASCO, DME, MISUMI, and PUNCH, they are designed to deliver impeccable results.

Crafted from premium materials like ADC12, ADC14, A360, A380, and AlSi9Cu3, the cast Aluminum molds undergo rigorous heat treatment, ensuring a hardness over HRC45.

You can choose from sandblasting, powder coating, painting, and anodizing finishes. And they are supported by a high-pressure die-casting process and backed by ISO 9001:2015 certification.

In conclusion, contact us today and add them to your inventory.

Trade information:

| MOQ | 1 set |

| Mold lead time | T1 sample, about 3-10 weeks, according to the mold requirement |

| Production lead time | 2-5 weeks, according to the order Qty |

| Mold payment term | 50% T/T deposit with PO, balance 50% T/T after sample approved |

| Products payment term | 30% T/T deposit with PO, balance 70% T/T before shipment |

| Port of loading | Ningbo or Shanghai port |

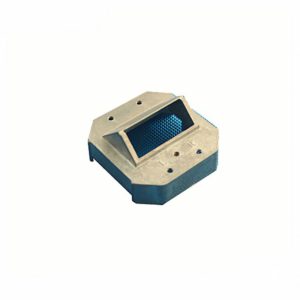

Some pictures of our die casting parts:

|

|

|

|

|

|