During the injection molding process, back pressure is applied from the backside of the screw inside the barrel. This helps the acre to push molten plastic material forward. This pressure exerted from the backside is referred to as backpressure. During backpressure injection molding, the screw would move backward without the back pressure, allowing the material to remain without changes throughout the barrel.

The injection molding machine has a screw circulated around the barrel at the back and a hydraulic motor. This backpressure helps to prevent the linear motion of the plastic particles inside the barrel. The amount of backpressure should be optimized to ensure the material comes out of the nozzle when charging. It shouldn’t be too high or too low. Backpressure can be kept only when two materials are mixed.

In the course of back pressure injection molding, drooling may occur due to constant backpressure. To prevent this, 4 mm or 10 mm backpressure is given. However, this will depend on the type and amount of material that linearly make the screen move.

Pressure is an integral part of injection molding. To understand this, it’s essential to know how injection molding works. The function of an injection molding machine is to mix, melt and mold plastics into various shapes and designs. This process starts with the plastic pellets being in the hopper. The pellets get moved through a heated barrel and get sheared by a plasticizing screw.

The shearing is made possible by a rotating screw that moves backward. This backward movement of the screw takes the melted plastics to the front of the screw with a volume of fluid. The fluid exerts a force on the screw, allowing a backward movement. The backward movement increases the volume in the melt chamber. However, this pressure must be controlled. This pressure is backpressure.

How backpressure affects injection molding

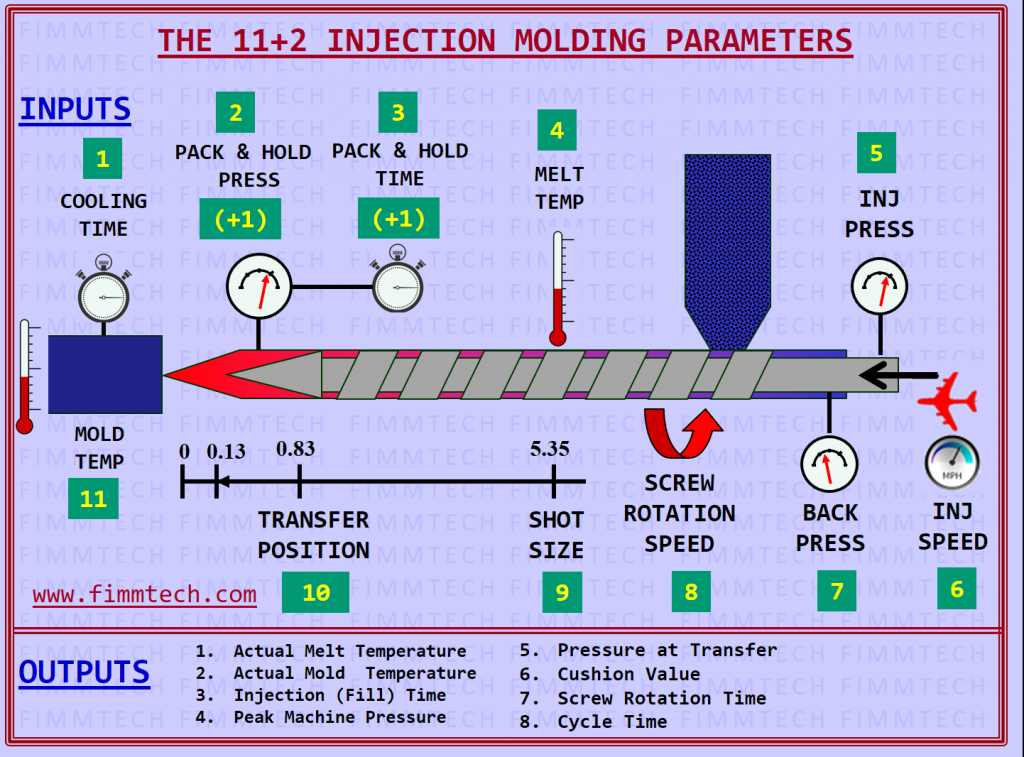

The success of the backpressure technique can affect the injection molding progress. The way the screw moves is vital since it does the bulk of the work. The molding process revolves around the back and forth motion of the screw. Here are some parameters to consider during backpressure injection molding;

●The speed of the screw measured in rotation per minute (rpm)

●The screw rotates between 20 and 60 rpm in most machines.

●The rotation speed depends on the properties of plastic.

●The size of the shot is also an important parameter to consider. This is determined by the injection chamber.

Things to know about backpressure injection molding

It’s crucial to know how backpressure occurs in the injection molding process to fully understand how the process gets controlled. The quality of the final product depends on how smoothly every event goes. Here are some essential roles of back pressure in injection molding.

Compacting

For more unified materials, pressure must be exerted on the melt. High pressure brings the molecules together and improves the density. Inadequate compact can result in a limited flow down the line. The back pressure not only controls the screw motion but also maintains the compacting pressure needed.

Venting

It’s challenging to prevent air from getting into the melt. This can result from the condensation of volatiles in the plastic that could also be from condensed air or liquid from the environment. The trapped air escapes and is driven by a pressure gradient that moves the trapped air from the melt chamber when the pressure is exerted.

The trapped air is moved to a lower region out of the system. Trapped air may not be visible on the product. However, it can result in a loss of functionality. It can also result in loss of design precision and surface imperfection. The injection molding machine can be fitted with a venting and decompression zone, which aids the effectiveness of such features.

Process timing

In the injection molding process, timing is crucial. A one-second difference in one cycle can have a significant impact on the product. Another process takes place as the screw moves back. The plastic melt from the previous cycle, for instance, cools off.

Hence, the backward movement of the screw needs to synchronize with the ejection of the product. When the screw stops moving back, the product will leave, and the mold closes. If a part of this process is halted, the whole process can be affected.

Shrinkage

The pressure exerted on the melt encourages isotopic shrinkage and reduces the impact of shrinkage. If the melt is under pressure, it may result in a reduction in the total volume. Consequently, back pressure in injection moulding allows for dimensional stability. Even when shrinkage occurs, the effect will be less pronounced.

Mold filling

The right pressure is required for the melts while filling the mold. The pressure must be sustained while the melt travels through the runners. The back pressure plays a role in the speed and pressure of mold filling.

Melt temperature

The temperature of a system increase in response to the pressure exerted. When the melt volume in the melt chamber increases, the space available to the melt is reduced by the backpressure.

The system increases the temperature, which in turn is achieved by applying backpressure. The increase in temperature decreases depending on viscosity which is excellent for mold filling and product formation.

In cases where the backpressure is too high, it can lead to the degradation of the plastic in plastics that are temperature sensitive.

Filled plastics

Extra care is necessary for materials filled with fibers as high injection molding back pressure can reduce fiber length. Breakage can also occur as a result of the compacting and increased shearing from backpressure.

Usually, plastics are filled with fiber to improve their properties. There are several recommendations from manufacturers for plastic products used in injection molding. It is essential to take into account the pressure the material can withstand.

Good control over backpressure is crucial to product quality. Engage the services of a reputable plastic injection molding company to get the best product for your business. Contact us for more information.