In the categories of die casting technology, magnesium die casting is a relatively new advancement that supports modern manufacturing where low weight and high strength matter.

Today at Moldie, we will show you how this die casting technique works, why specific magnesium alloys matter, and how design choices affect applications, cost, and performance.

Understand Magnesium Die Casting – What are the Differences

Magnesium die casting has a relatively recent history compared to longer-established methods. While zinc and aluminum die casting were industrialized in the early 20th century, magnesium’s commercial use only began gaining significant traction in the latter half of the 20th century, driven by military and aerospace demands for lightweight, strong components.

By basic principles, magnesium die casting is similar to other die casting processes that inject molten magnesium alloy into a steel mold under pressure. However, the traits of magnesium and its alloys lead to unique features.

In practice, however, magnesium die casting differs from aluminum and zinc die casting in several practical ways, because magnesium has low melting points, flows easily, and cools fast, which supports shorter cycle times.

In short, zinc offers excellent detail but adds more weight. Magnesium reduces mass while keeping excellent strength.

| Feature | Magnesium | Aluminum | Zinc |

|---|---|---|---|

| Density | Very low | Medium | High |

| Typical chamber | Hot | Cold | Hot |

| Cycle time | Short | Medium | Short |

| Part weight | Light | Moderate | Heavy |

Compared with other die casting methods, magnesium works best when weight reduction and speed are the most important.

Magnesium Alloys Used in Die Casting

There are a huge variety of magnesium alloys, and each of them has its unique features. Here we will generalize some of the common types based on these features.

General-Purpose & High-Strength Alloys

For housings, covers, and structural parts where a balance of strength, castability, and surface finish is key. AZ91D is the most widely used alloy. Excellent flow and good strength; ideal for consumer electronics housings, covers, and general components.

High-Ductility & Safety-Critical Alloys

Used where energy absorption and impact resistance are priorities, such as automotive safety components. There are mainly three types with one subvariant.

- AM60 / AM60B: Higher ductility than AZ91D. Common in steering wheels, seat frames, and interior structural parts.

- AM50: Similar to AM60 with slightly lower strength but higher impact resistance; used in impact-loaded components.

- AM20: For low-load parts where maximum toughness and ductility are required.

Elevated-Temperature & Creep-Resistant Alloys

Suitable for applications near engines, transmissions, or other high-heat environments. The AE42 & AS41 / AS41B alloys can handle higher operating temperatures, with AS41B offering improved creep resistance over AS41.

Here is a chart to help you scan through these alloy types:

| Alloy | Category | Key Use | Main Benefit |

|---|---|---|---|

| AZ91D | General-Purpose | Housings, covers, consumer parts | Best all-round: strength + flow |

| AM60 / AM60B | High-Ductility | Safety parts (steering wheels, seat frames) | High ductility, energy absorption |

| AM50 | High-Ductility | Impact-loaded parts | Toughness, impact resistance |

| AM20 | High-Ductility | Low-load, high-toughness parts | Maximum ductility |

| AE42 / AS41 | High-Temperature | Near engines/transmissions | Heat & creep resistance |

Step-By-Step Magnesium Die Casting Process

The magnesium die casting process is optimized to leverage the metal’s unique advantages—like its excellent fluidity and low melting point—while mitigating its specific challenges, such as oxidation risk.

Die Preparation & Heating

Magnesium’s excellent fluidity and rapid solidification require precise die temperature management. Dies are preheated to a higher, more uniform temperature (typically 250-400°C) compared to aluminum. This prevents premature chilling of the molten metal, which is essential for filling thin-walled sections and achieving a smooth surface finish.

Many manufacturers use thermal imaging to monitor the die. For magnesium, identifying and eliminating “cold spots” is crucial to prevent misruns and ensure consistent fill.

A thin, even lubricant is applied not only to aid release but also to provide a protective barrier, reducing the risk of magnesium soldering (sticking) to the die steel.

Injection: The Hot-Chamber Advantage

Magnesium die casting uses hot chamber machines in the majority of small-to-medium sized casting products, but large parts or special magnesium alloys can still be subjected to cold chamber die casting. The injection mechanism sits submerged in a bath of molten magnesium, allowing for:

- Faster cycle times (no need to transfer metal from a separate furnace).

- Reduced heat loss and better temperature stability.

- Higher precision in shot volume control.

Another special procedure during the transfer and injection of the molten magnesium is specialized cover gas shielding, because magnesium can be highly reactive and volatile, and its oxidation process can ruin the workpiece or even pose a safety hazard.

Finally, due to its low viscosity and superb flow characteristics, magnesium fills the die significantly faster than aluminum. This allows for the casting of complex, thin-walled parts (as thin as 0.5 mm) with exceptional detail.

Solidification & Cooling

The second-to-last stage of the whole process is the cooling of the workpiece. Since magnesium cools and solidifies significantly faster than aluminum. This leads to the shorter overall cycle times that make it economically attractive.

However, magnesium’s high shrinkage rate determines that the pressure in the chamber must hold, as it is critical to minimize porosity and ensure dimensional accuracy and part strength.

Ejection, Trimming & Finishing

The rest of post-processing procedure can be concluded in these three steps:

- Ejection: Parts eject easily due to magnesium’s low solidification shrinkage and minimal tendency to adhere to steel dies (when lubrication is correct). This reduces ejection force and minimizes part distortion or surface damage.

- Trimming: The excellent machinability of magnesium alloys makes trimming gates and overflows clean and efficient, with less tool wear compared to aluminum.

- Finishing: The inherently smooth “as-cast” surface of magnesium often requires less secondary finishing. When needed, it accepts coatings and anodizing well, but proper cleaning and surface preparation are essential due to its reactive nature.

Performance Advantages and Characteristics

Magnesium die cast parts combine low weight with strong mechanical performance and useful functional properties. These characteristics support designs that need strength, stability, and reliable performance under heat, stress, and electronic interference.

Strength-to-Weight Ratio

Magnesium offers one of the highest strength-to-weight ratios among structural metals. Raw magnesium weighs about 35% less than aluminum, while magnesium alloy parts can provide an impressive tensile strength between 150 and 250 MPa.

Die-cast magnesium alloys also provide good ductility, which allows parts to absorb impact without cracking. This trait is valued in automotive and handheld equipment.

Corrosion Resistance

Modern magnesium alloys deliver reliable corrosion resistance when paired with proper design and surface protection. Alloying elements such as aluminum and manganese help slow corrosion in normal environments.

Manufacturers often add coatings like anodizing, conversion coatings, or paint systems. These layers protect parts used in vehicles, electronics, and outdoor equipment. With these treatments, magnesium performs well in humid or mildly corrosive conditions.

Thermal Conductivity and Heat Dissipation

Magnesium alloys provide solid thermal conductivity, which supports fast and even heat dissipation. This feature helps reduce thermal stress and protect components that generate heat during operation, such as motors, power tools, and electronic housings. Furthermore, it also supports tighter packaging because designers rely less on added cooling hardware.

RFI Shielding and Other Functional Properties

Magnesium die castings offer effective RFI shielding due to their electrical conductivity. Enclosures made from magnesium block electromagnetic interference that can disrupt sensitive electronics. This property supports stable signal performance in devices like laptops, control units, and communication systems.

Magnesium alloy casting also offers good machinability and dimensional stability. This trait allows precise features without heavy secondary processing, saving time and cost while making sure the parts hold tight tolerances during use, even with temperature changes.

Applications of Magnesium Die Casting

Manufacturers use magnesium die casting when they need strong, precise, and lightweight parts at high volumes. The process supports complex shapes, thin walls, and tight tolerances across many industries.

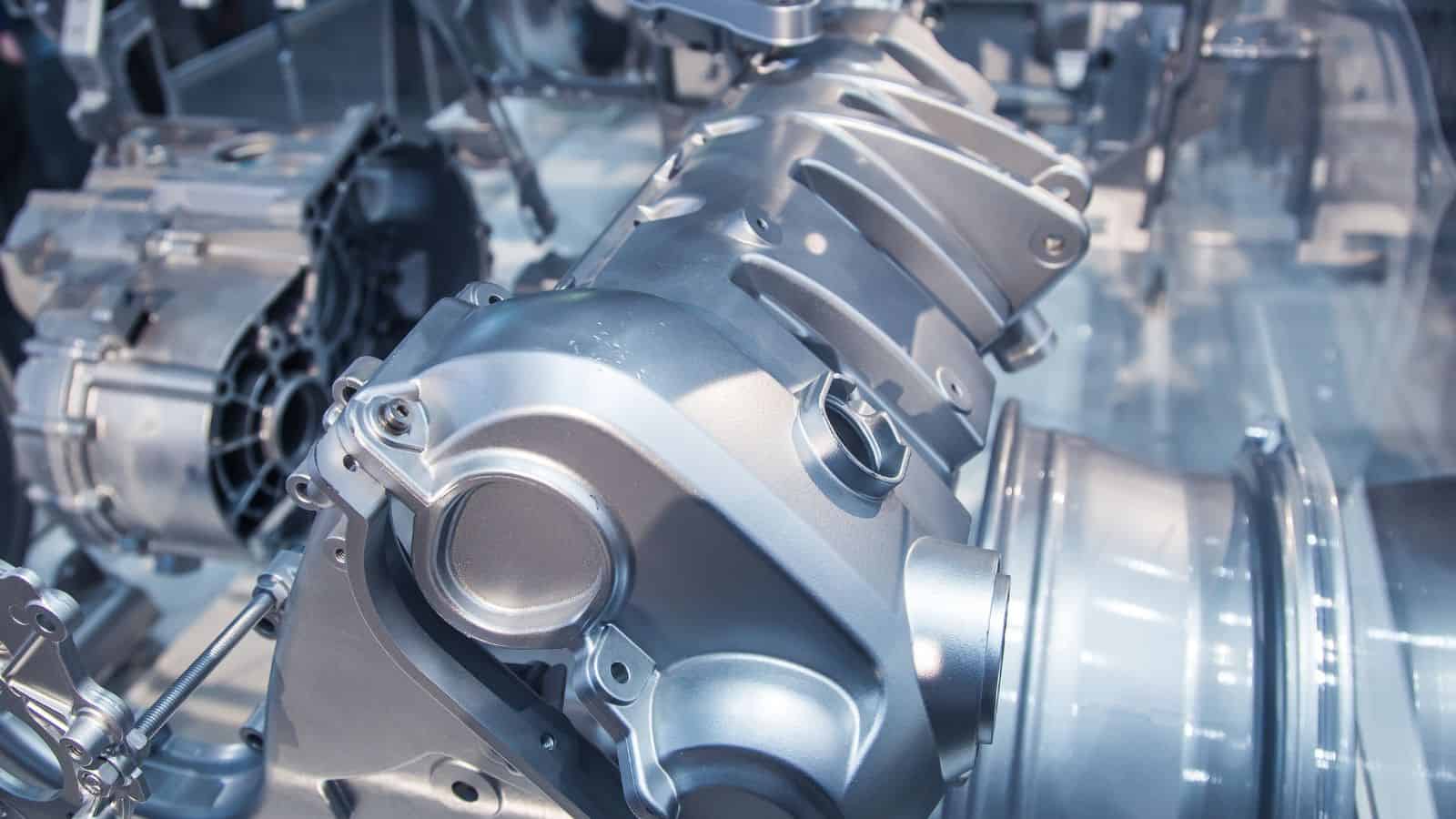

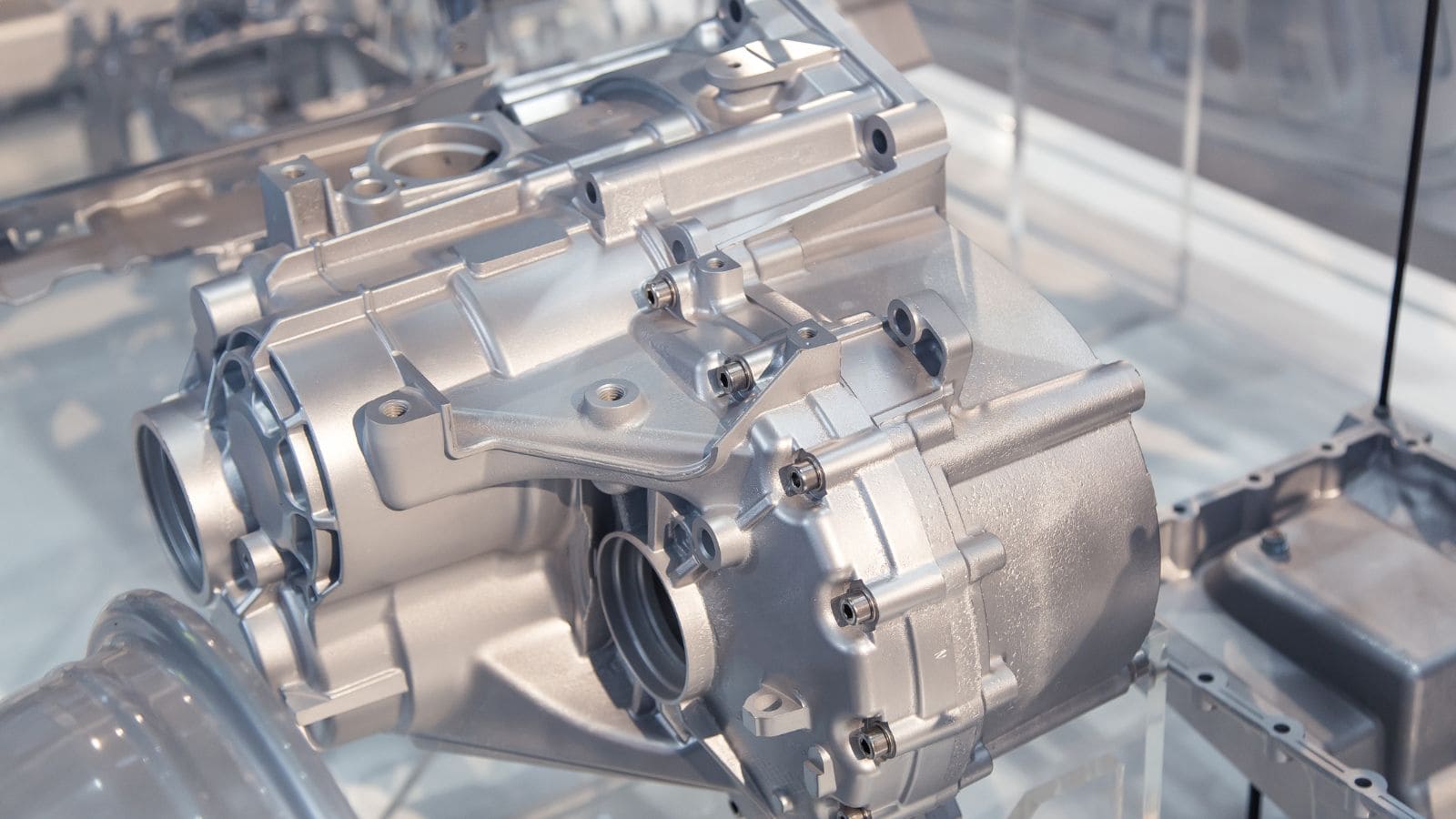

Electric Vehicle Components

The prospering electric vehicle market in recent years is perhaps one of the most prominent drivers for the magnesium die casting industry. Automakers use magnesium die-cast parts to reduce vehicle weight without losing strength, which improves driving range and energy efficiency in EVs. Common parts include battery housings, motor covers, inverter cases, and structural brackets.

Magnesium works well for seat components and interior supports. These parts must handle repeated loads while staying light.

Some engine and transmission components in hybrid systems also use magnesium. These parts benefit from accurate casting and good heat flow. Surface coatings protect them from corrosion and extend service life.

Key EV uses

- Battery and electronics housings

- Seat frames and interior structures

- Motor, gearbox, and powertrain covers

Consumer Electronics and Power Tools

Consumer electronics rely on magnesium die casting for thin, rigid enclosures. Laptops, tablets, and handheld devices use magnesium frames to stay light while resisting bending. The material also helps manage heat from processors and batteries.

Power tools use magnesium for gear housings, motor frames, and handles. These parts reduce tool weight, which lowers user fatigue during long tasks. High dimensional accuracy allows tight gear alignment and smooth operation.

Manufacturers also value fast cycle times and clean surface finishes. These traits support high-volume production and reduce post-processing work.

Common products

- Laptop and tablet frames

- Camera and audio equipment bodies

- Power tool housings and motor frames

Specialized and Custom Applications

Aerospace firms use magnesium die casting for aerospace components where weight savings matter. Parts such as brackets, housings, and support structures help lower overall system mass. Careful alloy choice and coatings address corrosion and safety needs.

Industrial equipment makers use magnesium for custom enclosures and structural parts. These lightweight parts improve handling and reduce shipping weight. Designers also use magnesium when they need complex shapes that other metals cannot form easily.

Low-volume or specialized projects often benefit from magnesium’s machinability. Manufacturers can adjust or finish cast parts with less effort and lower tool wear.