Magnesium Die Casting Solutions from China’s Leading Manufacturer

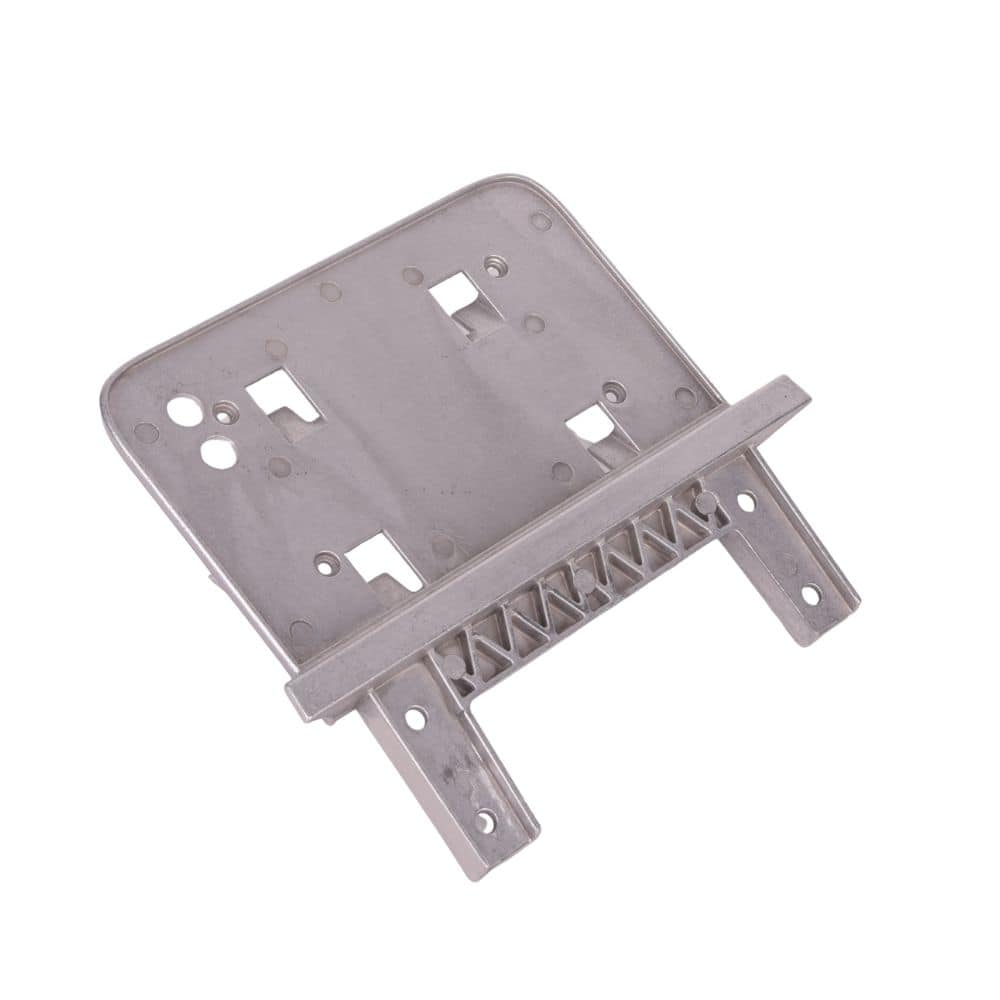

Moldie combines precision engineering with innovative materials to produce exceptional magnesium die casting parts in China. These components are designed for industries that require high performance and lightweight solutions, showcasing the highest standards of manufacturing quality. Our specialized die casting process guarantees excellent dimensional accuracy, smooth surface finishes, and outstanding structural strength.

Magnesium die casting offers distinct advantages in complex engineering applications due to its excellent strength-to-weight ratio. This makes the parts ideal for use in the automotive, aerospace, electronics, and industrial machinery sectors. Each component is carefully crafted to meet strict quality requirements, employing advanced technologies that enhance material properties and reduce production tolerances.

Advanced Manufacturing for Complex Geometries

Our manufacturing process utilizes advanced die casting techniques specifically designed for magnesium alloys. We are capable of producing complex shapes with tight tolerances, ensuring reliable performance across a wide range of applications. The lightweight characteristics of magnesium, combined with its excellent mechanical properties, offer engineers a versatile material solution without sacrificing structural integrity.

Our production workflow incorporates thorough quality control measures to guarantee that every magnesium die casting part produced in our factory in China meets exact specifications. From the initial design phase through to final product validation, our engineering team upholds rigorous standards of quality. We excel at turning complex design challenges into efficient, high-performance magnesium components that surpass client expectations.

Clients benefit from our dedication to technological innovation, deep material knowledge, and precision manufacturing expertise in magnesium die casting.

Basic information

| Brand | Moldie |

| Mold Base | LKM C50 + P20 for AB, Cast iron etc. |

| Inserts(cavity and core) | Dievar, H13, 8407, 1.2344 or the material you required |

| Standard | HASCO, DME, MISUMI, PUNCH and so on |

| Product Material | AZ91, ADC12, ADC14, A360, A380, AlSi9Cu3 and so on |

| Mold Treatment | Heat Treatment >HRC45 |

| Product Surface | Sand blasting, Powder coated, Painting, Anodizing, etc |

| Shape & Color | Can be design according to your needs |

| Process | High Pressure Die Casting |

| Certificated | ISO 9001:2015 Certificated |