Shot blasting is a very versatile surface processing technique that is suitable for both surface preparation and post-processing. In the following exposition, we will show you how the process works, what equipment it uses, and the types of abrasive materials involved, and offer you some insights on your production needs.

What Exactly Is Shot Blasting?

Definition and Purpose

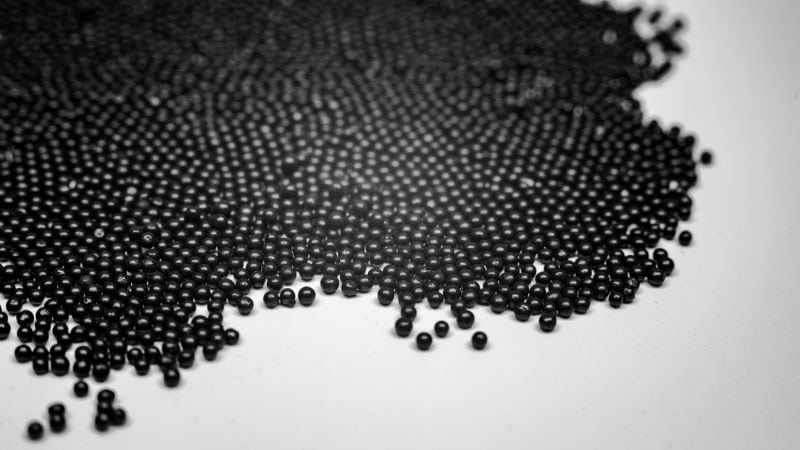

Shot blasting is a mechanical surface treatment process that uses spherical or angular abrasive media launched at high velocity. The process removes rust, oxidation, and contaminants while smoothing or texturing the material’s surface.

Different industries use shot blasting to treat metals, concrete, and other durable materials. It helps prepare workpieces for painting, coating, or bonding by ensuring the surface is clean and slightly roughened for better adhesion.

Unlike chemical cleaning, shot blasting uses physical impact to both clean and strengthen materials, and also improves fatigue resistance and stress corrosion. The repeated strikes of the abrasive media can also induce beneficial compressive stresses on the surface layer, a related process known as shot peening.

How Shot Blasting Differs from Sandblasting

“Shot Blasting” and “Sandblasting” are often used interchangeably, but they refer to distinct concepts within surface preparation.

Shot Blasting specifically describes a process that uses a centrifugal wheel to mechanically propel abrasive media at high velocity. The term “shot” strongly implies the use of spherical media (like steel shot), although angular media (grit) can also be used. This method is known for high efficiency and uniformity, making it ideal for high-volume or heavy-duty industrial applications.

Abrasive Blasting (or Grit Blasting) is the broader, more accurate umbrella term for all processes that clean or prepare a surface by forcibly propelling a stream of abrasive material against it. This can be done using:

- Compressed air (Pneumatic Blasting): The most common method for “sandblasting” cabinets, outdoor work, and detailed applications. It can use a vast array of media (sand, glass beads, walnut shells, steel grit, etc.).

- Centrifugal wheel (Mechanical Blasting): This is shot blasting, as defined above.

- Water with abrasive (Wet Blasting/ Hydro-blasting).

The key distinction lies less in the material treated and more in the propulsion method and typical application scale.

The Shot Blasting Process

Step-by-Step Workflow

The shot blasting process follows a sequence comprised of three key stages:

-

Loading & Blasting: The workpiece is secured within an enclosed chamber. A wheel then propels abrasive media at high velocity through centrifugal force, stripping away rust, scale, or previous coatings from the surface.

-

Media Recovery & Recycling: Used media and debris fall to the chamber floor. A recovery system separates clean, reusable abrasive from contaminant waste, while a dust collector maintains visibility and system efficiency.

-

Inspection & Adjustment: The prepared surface is evaluated for cleanliness and texture profile. Operators can fine-tune variables like media type or wheel speed to achieve the exact finish required for the next manufacturing step.

Surface Cleaning Techniques

Different cleaning methods suit different materials and surface conditions. Centrifugal wheel blasting works well for durable metals like steel or cast iron, while pneumatic (air) blast systems use compressed air for more delicate parts.

Abrasive media selection also affects the finish:

| Media Type | Characteristics | Typical Use |

|---|---|---|

| Steel shot | Round, strong | Polishing hard surfaces |

| Steel grit | Angular, sharp | Removing heavy rust or scale |

| Glass beads | Smooth, light | Cleaning soft metals |

Operators choose abrasive size based on how aggressive the cleaning must be. Smaller media produces a smoother finish, while larger grit cuts faster and roughens the material for better coating adhesion.

Shot Blasting Equipment and Components

Shot Blasting Machines

An enclosed shot blasting machine lies in the core of the entire system. Key components include:

- Blast wheel – generates and directs the abrasive flow.

- Control system – adjusts speed and flow rate of abrasives.

- Cabinet or chamber – contains the blasting zone for safety and efficiency.

Shot blasting machines are typically enclosed systems (cabinets, rooms, or continuous conveyor tunnels) that contain the abrasive and debris for recovery and recycling. This design is standard for component processing in manufacturing. For large, immovable structures like ships, bridges, or storage tanks, mobile shot blasting units are used in open environments, often without abrasive recovery.

Blasting Cabinets and Nozzles

A blasting cabinet provides a contained environment for smaller or more detailed work. Operators access the work area through glove ports while maintaining a sealed workspace to limit dust and abrasive loss. Cabinets often integrate nozzles that use either air pressure or wheel-driven force to propel media at the target surface.

Important features include durable lining materials, integrated lighting, and clear viewing windows for precision. Common abrasive media used inside cabinets are steel shot, steel grit, or ceramic beads, chosen by hardness and desired finish. Pressure-adjusted nozzles control the cleaning intensity, allowing operators to handle delicate parts without surface damage.

| Component | Function |

|---|---|

| Cabinet body | Contains abrasive and debris |

| Gloves & viewing window | Allows control and visibility |

| Nozzle | Directs abrasive stream |

Recovery and Filtration Systems

Recovery systems gather used abrasive materials for cleaning and reuse. A typical setup includes bucket elevators, separators, and storage hoppers. These parts collect the spent media, remove dust or broken particles, and feed the cleaned abrasive back into the blast wheel or nozzle.

The filtration system, often a dust collector, removes fine particles from the air to maintain visibility and protect operators. Filters may include cartridge, bag, or cyclone types, depending on the machine’s size and airflow capacity. Efficient recovery and dust control extend media life, reduce waste, and support a safer work environment.

Abrasive Media Types

Steel Shot and Steel Grit

Steel shot and steel grit are metallic abrasives made from high-carbon or stainless steel. Their spherical shape delivers uniform peening and cleaning, reducing stress points on metal parts. Industries use steel shot to remove rust, scale, and paint from steel structures or to strengthen automotive and aerospace components.

They come in multiple sizes and hardness levels. Hardened steel shot (around 50–60 HRC) fits heavy-duty operations, while softer grades (20–30 HRC) suit aluminum and non-ferrous metals. The shots’ durability allows multiple reuse cycles and consistent surface results.

| Property | Typical Range | Benefit |

|---|---|---|

| Hardness | 40–60 HRC | Higher wear resistance |

| Density | ~7.8 g/cm³ | Strong impact energy |

| Reusability | up to 100 cycles | Cost efficiency |

Shot blasting with steel media also supports surface profiling that improves paint or coating adhesion. When properly filtered and recycled, it offers a cost-effective and environmentally controlled finishing process.

Glass Beads and Aluminum Oxide

Glass beads clean, peen, and finish surfaces without removing excessive base material. They produce a smooth, satin-like texture on metals, plastics, and composites. Because beads are non-metallic and chemically inert, they do not cause corrosion or contamination. Their round shape minimizes surface damage, making them useful for precision or decorative work such as turbine blades and medical tools.

Aluminum oxide, in contrast, is a sharper, angular abrasive. It cuts faster and removes coatings, rust, and burrs efficiently. Its hardness (about 9 on the Mohs scale) makes it suitable for tough alloys and steel components that require deep surface cleaning or etching.

While glass beads prioritize a gentle finish, aluminum oxide favors aggressive abrasion for profiles needing coating adhesion. Both materials can be recycled several times but require different blasting pressures and nozzle setups to perform optimally.

Other Abrasive Materials

A wide range of other abrasive media serves more specific goals. Plastic media, made from urea or melamine, removes coatings from softer metals and composites without distortion. Walnut shells and corn cob abrasives clean delicate surfaces and absorb oils in automotive and aerospace maintenance. These organic options reduce heat buildup and prevent damage to lightweight parts.

Copper slag, garnet, and ceramic grit offer midrange hardness and are common where silica sand is restricted for safety reasons. These materials deliver controlled roughness, making them suitable for marine structures or construction steels.

Selecting the right abrasive depends on hardness, density, particle shape, and recyclability. Matching these factors to the target surface ensures both performance and cost control in the shot blasting process.

Applications and Industry Uses

Manufacturing and Metalworking

Manufacturers use shot blasting to clean castings, forgings, and fabricated metal parts before painting, coating, or welding. Removing oxide layers and residues ensures coatings bond properly and improves overall durability. This process is common in production lines that handle steel plates, beams, and machinery parts.

Foundries rely on tumbling or conveyor-type blast machines to treat batches of small or medium components. The procedure not only cleans but also strengthens metal surfaces through controlled abrasion.

Typical uses include:

- Cleaning cast iron or steel components

- Removing welding slag or heat treatment scale

- Preparing gears, springs, and tools for finishing

By maintaining a uniform surface texture, manufacturers can achieve better quality control and longer product life.

Construction and Shipbuilding

In construction and shipbuilding, shot blasting helps prepare large steel structures for protective coatings. Steel beams, bridges, and ship hulls often require deep cleaning to remove corrosion and improve paint adhesion. This preparation reduces the chance of coating failure in harsh environments.

Surface treatment machines built for heavy-duty work handle beams, plates, and welded assemblies. These systems operate continuously to process large volumes of material used in ships, pipelines, and offshore platforms.

Common benefits include:

| Purpose | Result |

|---|---|

| Rust and scale removal | Cleaner metal surfaces |

| Improved paint adhesion | Longer coating life |

| Uniform surface texture | Better weld quality |

Regular shot blasting in shipyards ensures that vessels maintain consistent structural integrity and meet inspection standards.

Aerospace and Specialized Components

Aerospace production depends on precise surface preparation to maintain component strength and accuracy. Shot blasting removes contaminants from engine housings, landing gear, and aluminum parts without altering their dimensions.

Specialized media such as ceramic or glass beads are often used to achieve smoother finishes and avoid damage to softer metals. Controlled blasting also helps create surfaces that improve fatigue resistance, especially in high-stress components.

Precision cleaning supports other finishing steps, such as coating or bonding, where any contamination could weaken performance. In these environments, strict process control ensures each part meets industry safety and quality standards.