Metal Surface Treatment

Metal Surface Treatment

Metal surface treatment refers to a variety of processes applied to the surface of metal components to enhance their properties and performance. These treatments can improve characteristics such as corrosion resistance, wear resistance, adhesion, and aesthetic appearance.

In Moldie, we provide various metal surface treatment service: electroplate, coating, printing, anodizing, laser, polishing, shot blasting and sticker.

In Moldie, we provide various metal surface treatment service: electroplate, coating, printing, anodizing, laser, polishing, shot blasting and sticker.

Request a Quote

Metal Surface Treatment

Metal surface treatments modify the metal’s external layer. You can use various processes like coating, plating, or electroplate, each having distinct purposes.

Electroplate

Electroplating is a process where you coat a metal object with a thin layer of another metal. This makes it shiny and resistant to corrosion.

Moldie Service: galvanization, nickel plate, and chrome plate.

- Nickel Plating: This is often used to create a smooth, shiny surface. It is frequently seen on bathroom fixtures and car parts because it resists wear and tear.

- Chrome Plating: Known for its reflective finish, chrome plating is popular for automotive trim and accessories. It comes in bright and matte finishes, allowing for different styles.

- Galvanization: Although not exactly electroplating, it involves coating iron or steel with zinc. This protects against rust, making it ideal for outdoor structures.

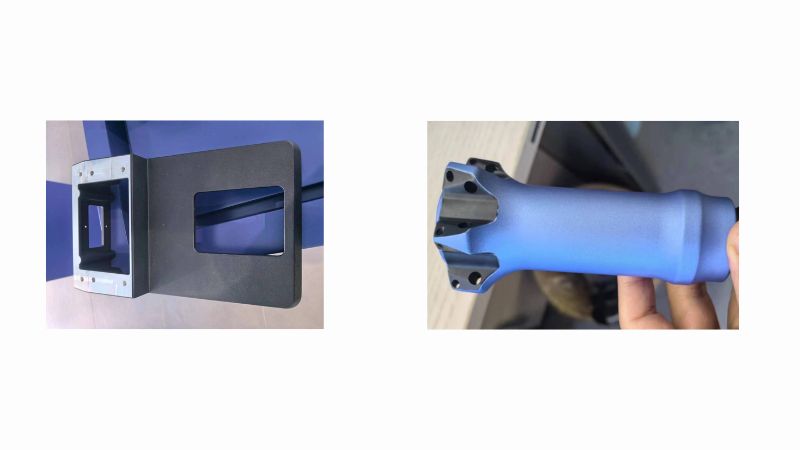

Coating

Coating metal surfaces gives them a protective layer and enhances their appearance.

Moldie Service: powder coating, stoving varnish, electrophoretic paint, ceramic coatings, and Teflon coatings.

- Powder Coating offers a wide range of color options and can be applied with various textures like matte and sanding. It’s great for durability and requires baking to harden. You can choose from many colors to fit your style.

- Stoving Varnish is another versatile option. This coating comes in multiple colors, and the thickness can be adjusted to suit your needs. However, thicker coatings might affect the fitting of threads.

- Electrophoretic Paint can achieve a glossy finish. This method provides a uniform coat, and while black is a common option, other colors are also possible. Moldie provides professional black electrophoretic paint.

- Ceramic Coatings add both beauty and heat resistance. These coatings can withstand temperatures below 600 degrees and are available in various colors. They provide a hard, durable surface that stands up to wear.

- Teflon Coatings offer non-stick properties and can also handle temperatures below 600 degrees. They are also available in multiple colors.

Printing

Moldie Service: pad printing and screen printing.

Pad Printing

This method is excellent for applying detailed designs. It’s particularly effective on flat surfaces. You can achieve single-color (monochrome) prints with ease. The process uses a silicone pad to transfer ink from a plate to the metal surface.

Screen Printing

Screen printing is versatile and works well for different shapes and sizes. It’s a bit like creating a stencil on the metal surface. You lay ink through a mesh screen where the design is open, and it results in vibrant prints. Priming the surface can enhance ink adhesion.

Anodizing

Moldie Service: anodizing.

Anodizing creates an oxide layer through an electrochemical process. This layer adds durability, corrosion resistance, and even decorative appeal.

Anodizing can produce vibrant, long-lasting colors. This can be handy if you want your metal parts to stand out or match a specific design. Plus, it resists fading over time.

Metals like aluminum, titanium, and magnesium can be anodized. The thickness of the oxide layer can range from a tiny 0.5 µm to a much thicker 150 µm, providing different levels of protection.

Laser

Moldie Service: laser.

They can make metals tougher and more resistant to wear. This is called laser hardening. It uses a laser to heat the metal’s surface quickly, which improves the metal’s hardness.

If you want metal surfaces with unique patterns, lasers can help you here too. You can create all kinds of patterns and designs, even typing or drawing on a product with precision. This process, known as laser structuring, can be used on almost any metal, including steel and aluminum.

Polishing

Moldie Service: polishing.

When you’re working with metal, polishing is a key step to make the surface smooth and shiny. You often use this process for aesthetic purposes and to improve durability.

There are different types of polishing techniques you might use. The higher the hardness of the metal, the easier it is to polish.

Shot Blasting

Moldie Service: shot blasting.

Shot blasting is a technique that you might encounter when dealing with metal surfaces. It’s like giving the surface a strong scrub to get rid of rust, paint, or other debris. This process helps prepare metal surfaces for further treatment or coating.

In shot blasting, tiny particles called “shots” are thrown at high speeds onto the surface. These particles can be made of materials like steel or cast iron. Their impact helps to clean and smooth out the surface. Imagine a rainstorm of small steel balls hitting metal, which keeps everything clean and ready for the next step.

One big advantage is that it makes the surface look uniform and neat. When you work in industries like automotive or aerospace, having clean surfaces is really important. This method not only cleans but also enhances surface quality, making sure everything is ready for use or further processing.

Sticker

Moldie Service: water applique.

Water applique sticker is a revolutionary surface treatment technology. This innovative process utilizes a thin film with a pre-printed design that is applied to the metal surface using water and pressure.

Water applique stickers can be printed with any imaginable design, from intricate patterns and logos to realistic images and textures. This allows for complete customization and personalization of metal objects, making them truly unique and eye-catching.

The water applique film is highly resistant to scratches, abrasions, and chemicals, ensuring that the design remains vibrant and protected for years to come.