Aluminium Die Casting Mold

If you are wondering why there is a high demand for products made using the aluminum alloy die casting mold, it is because these products are the best, with loads of benefits. The best thing about these products is that you can order customized aluminum die casting molds for your aluminum box, and have them delivered to your location without delay.

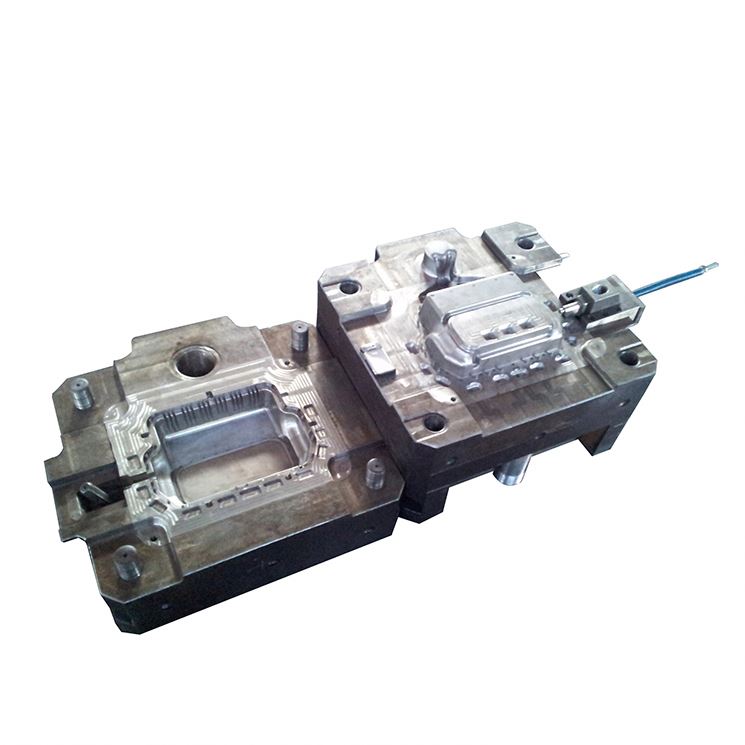

The die casting process is quite unique, so it is best that experienced alloy production experts handle it. They work with the molten metal of high-grade aluminum alloy to get the complex shapes from the die cast molds.

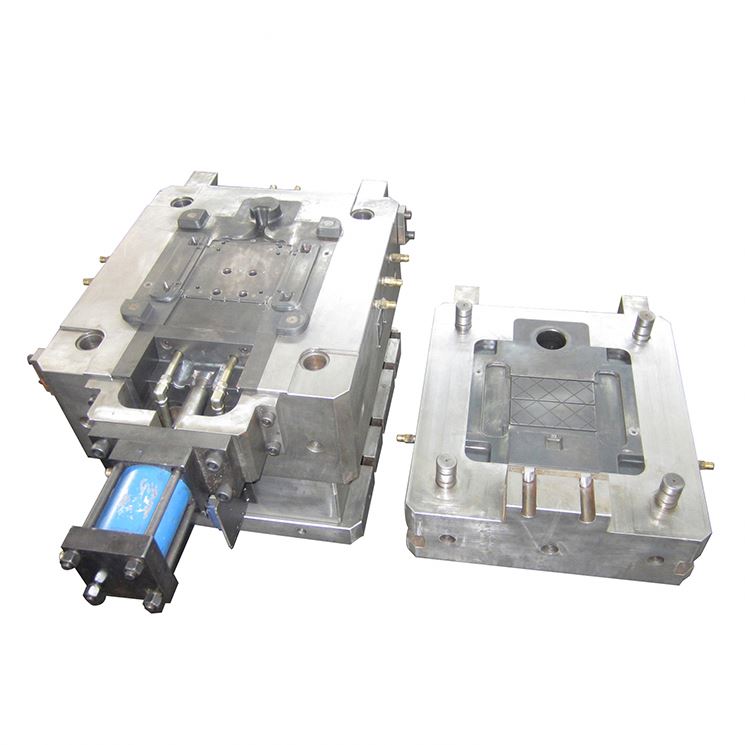

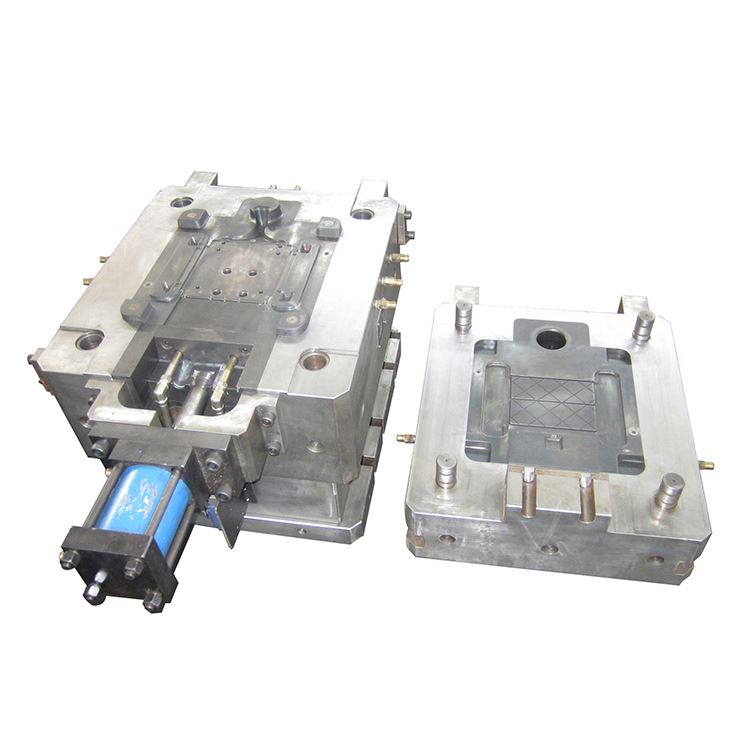

Molten aluminum is best used for aluminum die casting machined mold design under high pressure. The manufactured die halves are suitably enhanced for the fill process, and only high quality raw materials are used for the large scale production operations we do at our company.

Getting the Best Products

We have established our company to provide excellent metal casting products regardless of high production cost. Our prices are reasonable, and we ensure the CNC machining, tool, and other aspects of the aluminum die casting process meets your expectations.

We have made it so easy for you to access these aluminum alloy castings. Send us your customer contact form, and we will reply to start a correspondence, helping you order from us.

Why Using High-Grade Aluminum Die Cast Mold is Best

Over the years, we have found multiple reasons to continue using the best aluminum die casting molds for our jobs. Here are the top reasons why:

Large Scale Production

We have been able to meet the huge demands from our clients by producing enough die casting parts according to the order. We meet our deadlines because the molds can be used to produce multiple parts. And we have many of these molds made of high quality steel. The casting process is seamless because of our huge investment in ensuring everything needed for the production process is available.

High Pressure Tolerance

The production process happens under high pressure. Therefore, it is essential that the mould cavity can withstand high temperatures and pressure.

Lower Production Cost

The production cost is significantly lower compared to other production options. Considering that one high productivity mold can be used with multiple cavities to achieve thin walls, we continue to use the single mold or doubles with intricate features.

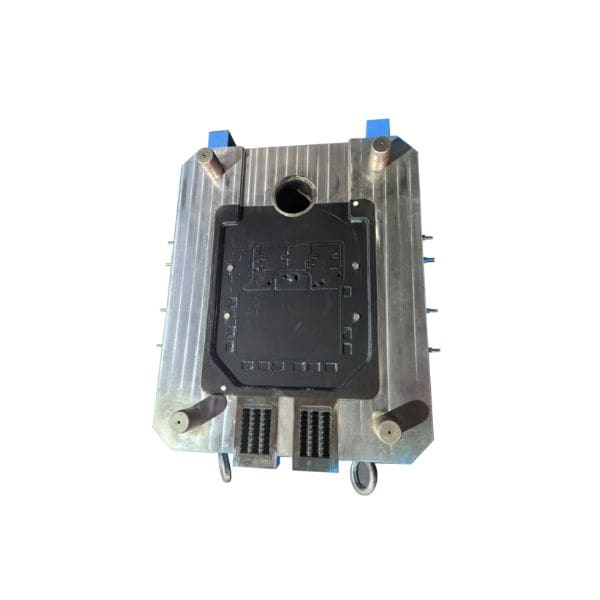

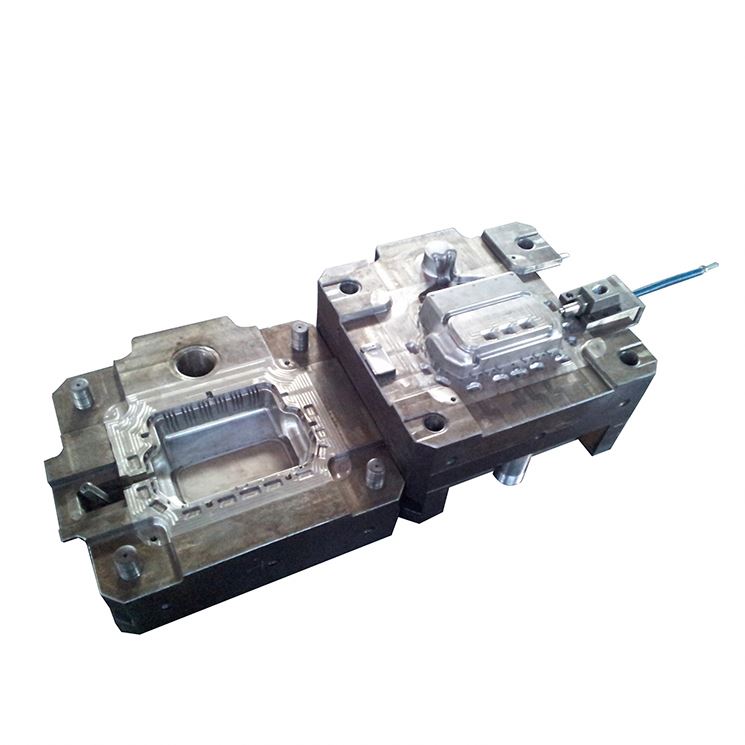

Product Description – Die Casting Mold for Aluminum Box

The following features further explain why our die casting molds are the best on the market:

Base Designs

We can meet diverse requirements from our clients because our production processes include using mold base like the LKM C50 + P20 for AB plastic, cast iron etc.

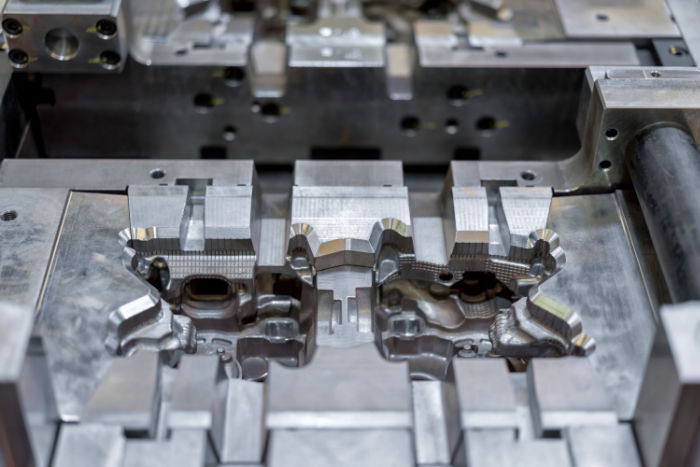

Cavity and Core Inserts

The basic materials we use for the inserts for cavities and the core are Dievar, H13, 8407, and 1.2344 ratings. However, we can make special arrangements for your order if you require particular materials, precision, or production temperature, at a reasonable machine tooling cost.

Product Material Standards

All our product materials, including the molten metal, are up to the HASCO, DME, MISUMI, and PUNCH standards. These standards apply to product materials like the ADC12, ADC14, A360, A380, and AlSi9Cu3.

Mold Treatment Standard

For the best results, we use the heat treatment HRC45, which is excellent for these hot chamber metal casting processes.

In addition, we offer clients options for die casting product finishing like Sandblasting, Powder coating, Painting, Anodizing, etc, and the final shape and color after aluminum die casting can be customized to meet your project requirements.

The accuracy level is excellent, without an additional inch, because we use the proper draft for the die-cast and parting line for the first inch during manufacturing components.

Order Aluminum die casting Molds in Bulk

We guarantee a lead time of 2 to 5 weeks for the aluminum die casting process and delivery. Send us your customer contact form to order these excellent molds for aluminum die casting boxes.