Total Solution for Molds & Dies

Bring Your Ideas to Life with Speed, Precision, and a Competitive Edge

Our Services

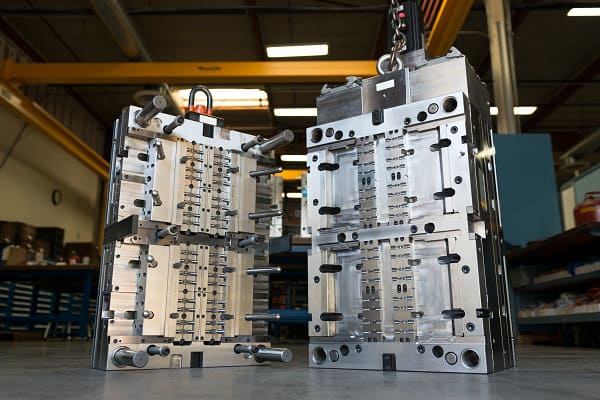

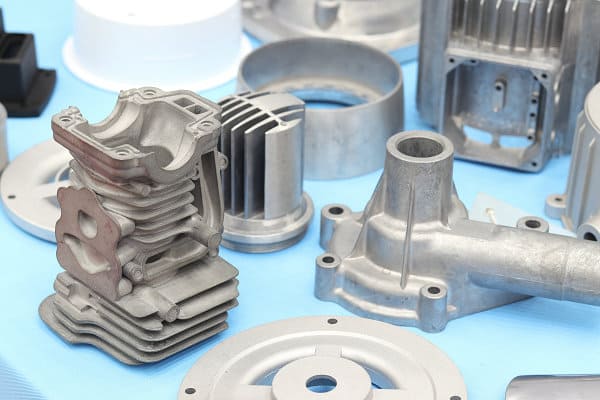

Comprehensive OEM/ODM Services for Plastic Injection Molds, Die Casting Dies, and Precision Mechanical Parts

About Moldie

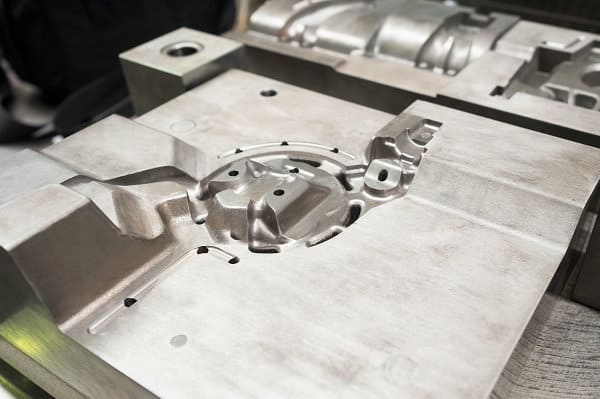

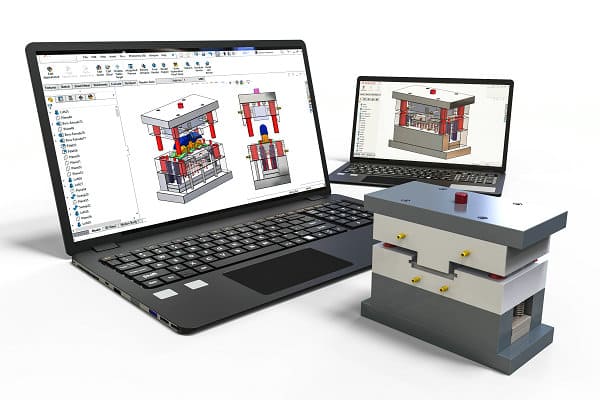

Founded in 2008, Moldie is at the forefront of crafting superior-quality plastic injection molds, die casting dies for Aluminum, Zamak and Magnesium, as well as precision mechanical parts. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, mold production, and/or large-scale production.

Our expertise has led us to collaborate with an array of international clients across various industries. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, BMW, Ferrari, Rolls Royce, and so on, to leaders in other fields such as Schneider, Phillip, and IEK, Moldie’s global footprint is ever-expanding.

Our Workshop

Inside Our Workshop: Exploring State-of-the-Art Manufacturing Excellence

Trusted By

Partnering with Industry Leaders for Exceptional Service